Precision silicon carbide ceramic components for lithography machines

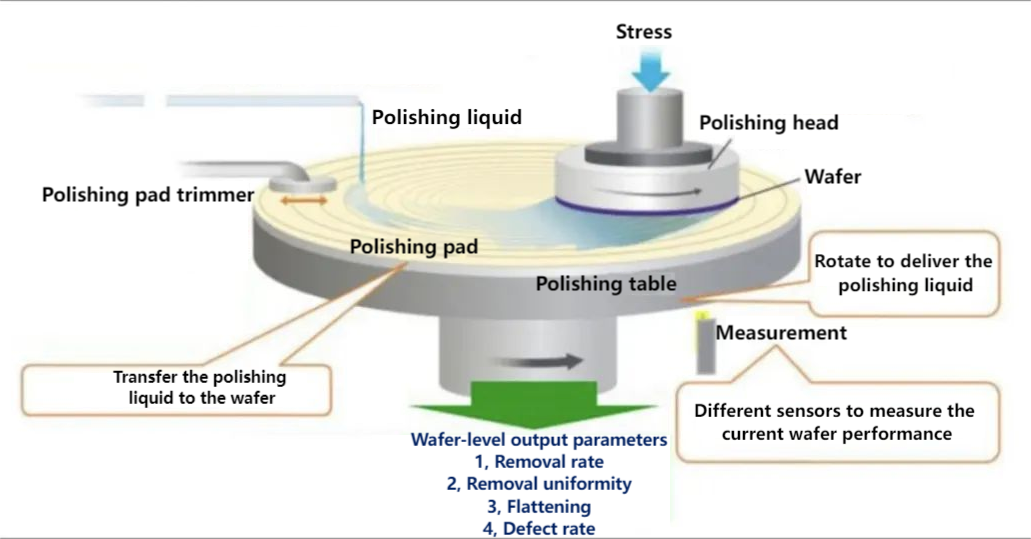

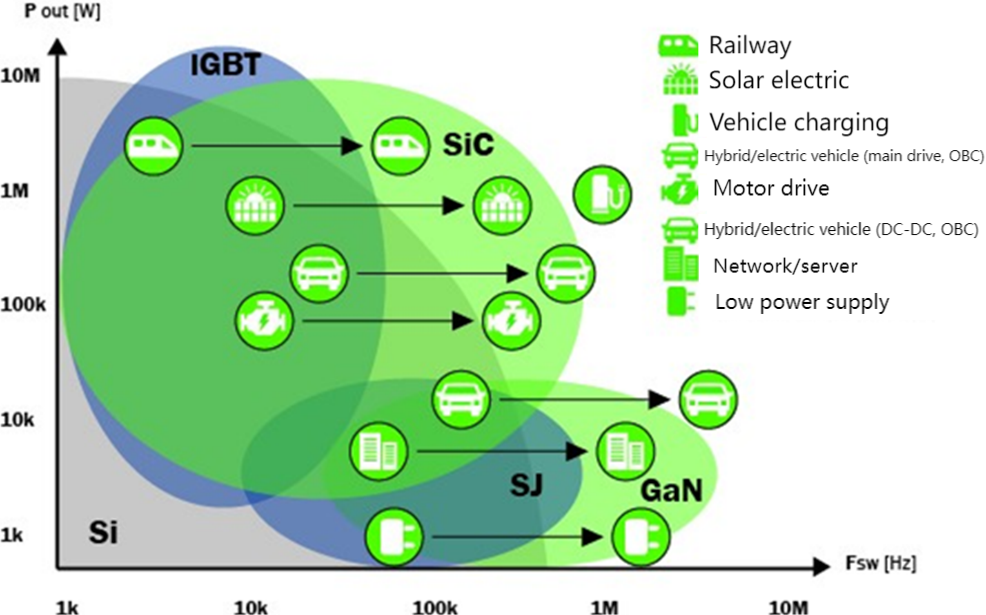

In the IC industry, integrated circuit manufacturing equipment has an extremely important strategic position. The key technologies and equipment of integrated circuit manufacturing mainly include lithography technology and lithography equipment, film growth technology and equipment, chemical mechanical polishing technology and equipment, high-density post-packaging technology and equipment...etc., all involve motion control technology and drive technology with high efficiency, high precision and high stability. The accuracy of structural parts and the performance of structural materials have very high requirements.

1、Characteristic requirements of precision ceramic structural parts for semiconductor equipment。

The key equipment of integrated circuit manufacturing requires the materials of parts to have the characteristics of high purity, high density, high strength, high elastic modulus, high thermal conductivity and low thermal expansion coefficient, and the structural parts to have extremely high dimensional accuracy and structural complexity to ensure the equipment to achieve ultra-precision movement and control.

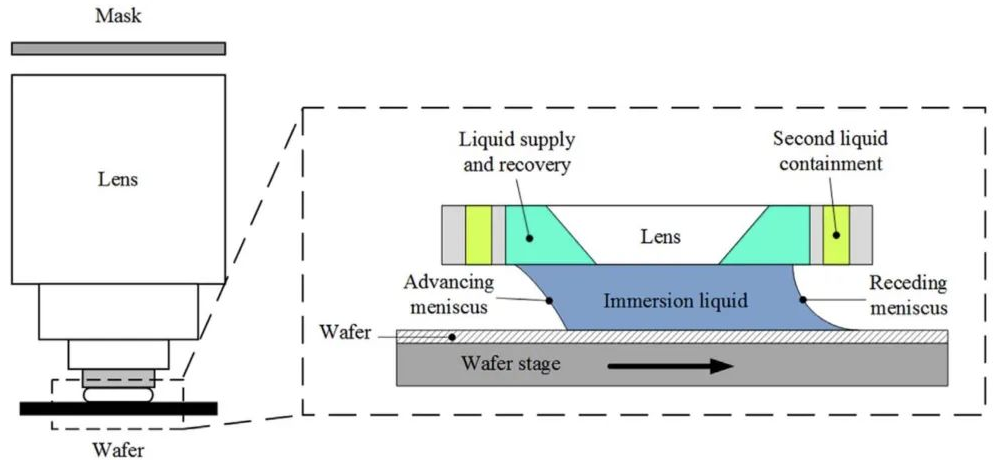

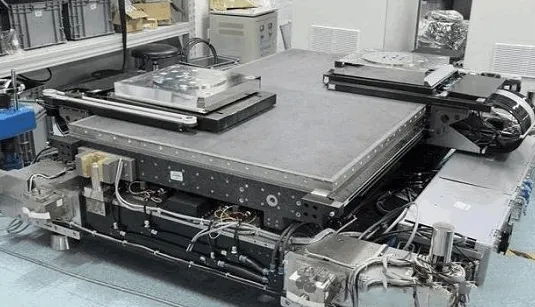

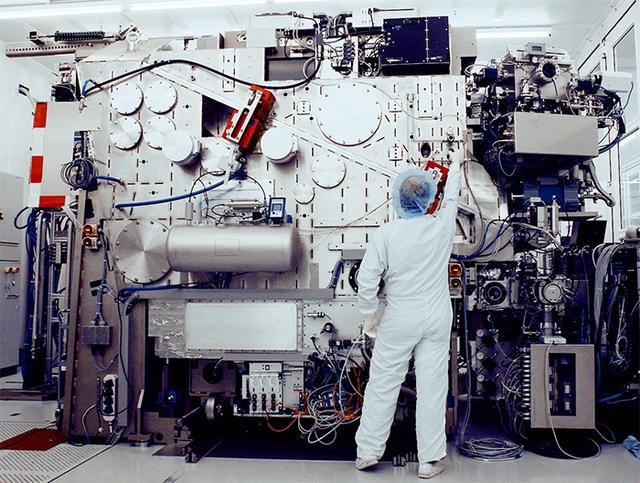

Taking the workpiece table in the lithography machine as an example, the main function of the workpiece table is to carry the silicon wafer and mask and complete the exposure process, and its performance directly affects the yield and resolution. It is required that the table can achieve high-speed and stable large stroke and nanoscale ultra-precision movement of six degrees of freedom. For example, for a lithography machine with a resolution of 100 nm, an engraving accuracy of 33 nm and a line width of 10 nm, the positioning accuracy of the workpiece table is required to reach 10 nm. The simultaneously stepping and scanning speeds of the mask-silicon wafer reach 150 nm/s and 120 nm/s respectively, and the mask scanning speed is close to 500 nm/s, and the workpiece table is required to have very high motion accuracy and stationarity.

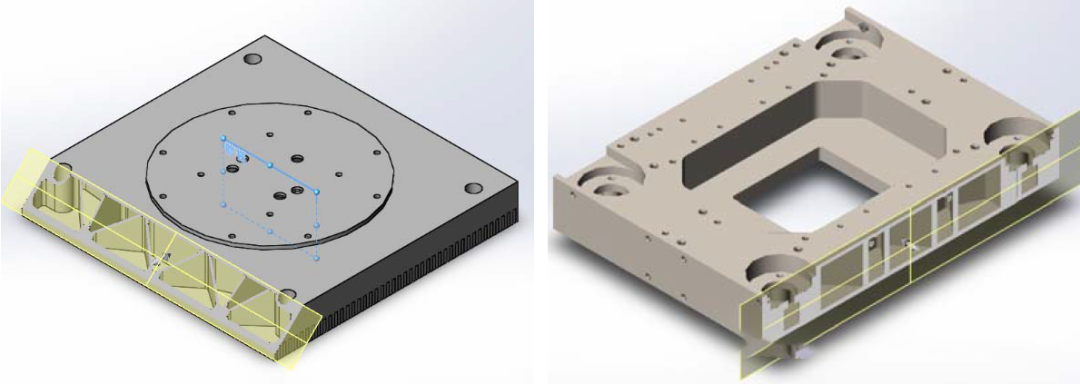

Therefore, the precision structural parts of the workpiece table need to meet the following requirements: (1) Highly lightweight: in order to reduce the motion inertia, reduce the motor load, improve the motion efficiency, positioning accuracy and stability, the structural parts generally use lightweight structural design, the lightweight rate is 60% ~ 80%, up to 90%; (2) High form and position accuracy: In order to achieve high-precision movement and positioning, the structural parts are required to have extremely high form and position accuracy, the flatness, parallelism and perpendicularity are required to be less than 1μm, and the form and position accuracy is required to be less than 5μm; (3) High dimensional stability: In order to achieve high-precision movement and positioning, the structural parts are required to have extremely high dimensional stability, which is not easy to produce strain, and the thermal conductivity is high, the thermal expansion coefficient is low, and it is not easy to produce large dimensional deformation; (4) Clean and pollution-free: structural parts are required to have very low friction coefficient, small kinetic energy loss during movement, and no grinding particle pollution.

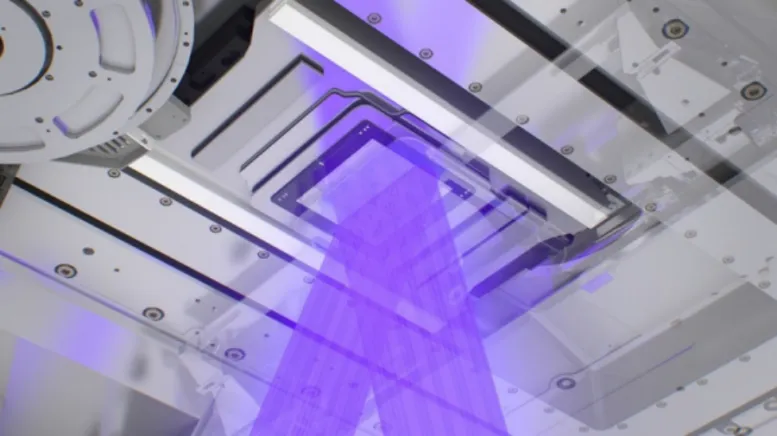

2,Application of silicon carbide ceramics in lithography machine

Silicon carbide is an excellent structural ceramic material with high strength, high hardness, high elastic modulus, high specific stiffness, high thermal conductivity, low thermal expansion coefficient and excellent chemical stability, which is widely used in petrochemical industry, machinery manufacturing, nuclear industry, microelectronics industry and other fields. Silicon carbide has a very high elastic modulus, thermal conductivity and moderate thermal expansion coefficient, has excellent polishability, can be processed into high-quality mirror, and is not easy to produce deformation and thermal strain. Through the special weight reduction structure design, the structural parts can be highly lightweight, which is widely used in the field of integrated circuit manufacturing equipment. Silicon carbide ceramics have excellent mechanical properties at room temperature, excellent high temperature stability and good specific stiffness and optical processing properties, especially suitable for the preparation of photolithography machine of integrated circuit equipment for precision ceramic structural parts, such as SiC ceramic workpiece table for photolithography machine, guide rail, mirror, ceramic chuck, arm, water-cooled disc, chuck...etc.

3,Technical difficulties of silicon carbide structural parts for semiconductor equipment

The precision ceramic structural parts used in the core equipment of integrated circuits have the characteristics of "large, thick, empty, thin, light and fine". However, because silicon carbide is a covalent bond compound with strong Si-C bond, it has high hardness and significant brittleness, and it is difficult to precision machining. In addition, the high melting point of silicon carbide makes it difficult to achieve dense and near-net size sintering. There are many technical difficulties and challenges in the preparation of silicon carbide structural parts:

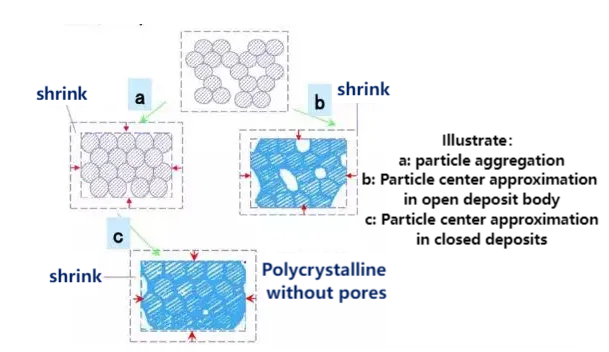

(1) How to realize the hollow closed cell structure to achieve the goal of high lightweight, for metal structural parts with hollow closed cell structure, brazing and diffusion welding processes are usually used; However, for the complex and immature metal structural parts, it is easy to form an obvious connection interface, resulting in the composition and performance with big difference between the connection layer and the matrix.

(2) How to achieve the high form and position accuracy of silicon carbide structural parts to achieve the goal of high-precision movement and positioning. The hardness of silicon carbide is second only to diamond, resulting in low processing efficiency and high processing cost of silicon carbide structural parts, so the realization of high shape and position accuracy of silicon carbide structural parts is also a technical difficulty, especially in the preparation of samples with large size, ultra-thin, complex structural characteristics and samples with hollow closed cell structure, the problem is particularly prominent.

(3) How to reduce or avoid the residual stress of silicon carbide products in the process of molding, drying, sintering and subsequent precision processing, and improve product quality and yield. Silicon carbide body in the drying and sintering process, because of the elimination of water and the loss of organic matter, easy to produce uneven shrinkage, resulting in cracks and deformation in the body, and the introduction of residual stress in the body, and in the precision processing process after sintering, it is possible to cause cracks inside the product, resulting in cracks, reduce the product yield. The preparation of large size, complex shaped hollow structure of precision silicon carbide structural parts is difficult, currently the silicon carbide ceramics market for integrated circuit manufacturing equipment is mainly occupied by foreign enterprises, Japan- Kyocera, USA- CoorsTek, Singapore-Fountyl. The research on preparation technology and application promotion of precision silicon carbide structural parts for integrated circuit equipment in China started late, and there is still a gap between China and the international leading enterprises.