Semiconductor ceramics - kev cai tsim

Ceramic caj npab Txheej txheem cej luam

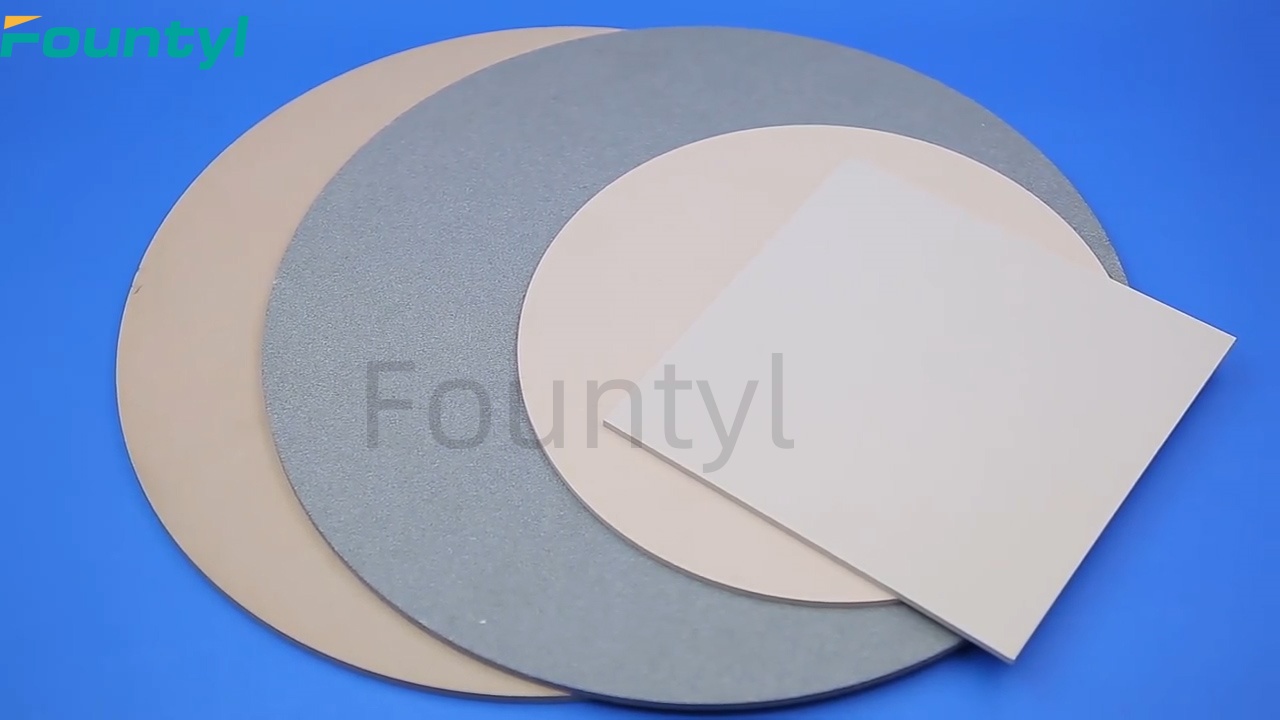

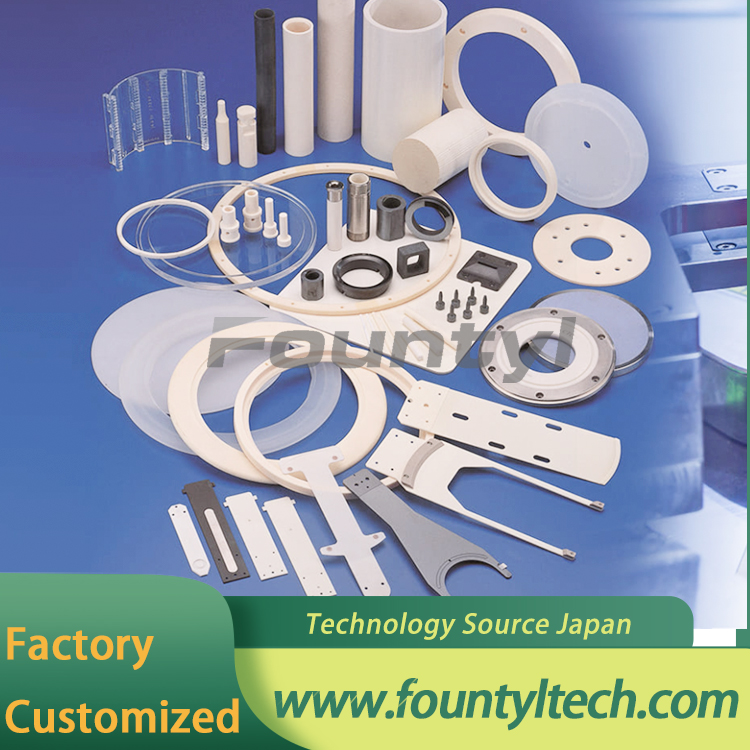

Vim qhov kev xav tau rau siab precision thiab durability nyob rau hauv cov txheej txheem tsim, kev lag luam semiconductor siv cov ntaub ntawv tshaj lij los tsim cov khoom. Cov txheej txheem ceramics yog qhov kev xaiv zoo tshaj plaws vim lawv qhov hnyav hnyav thiab tshuaj lom neeg inertia, nrog rau lawv lub peev xwm los ua ultra-precision machined kom ua tiav qhov xav tau precision. Ceramic semiconductor Cheebtsam ua los ntawm alumina ceramics tso cai rau koj kom ua tiav qhov zoo tshaj plaws thiab muab koj cov neeg siv khoom zoo tshaj plaws semiconductor qhov chaw. Peb muaj peev xwm ua tau raws li kev lag luam-ua precision tswj theem: yam tsawg kawg nkaus tolerances ntawm 0.001mm thiab yam tsawg kawg nkaus roughness ntawm Ra 0.1μm. Qhov chaw qis qis txo qhov kev pheej hmoo ntawm kev cuam tshuam tsis zoo ntawm wafer geometry.

Cov khoom muaj

※ Compact ceramics / ntxeem tau ceramics

※ Alumina (Al2O3 alumina), purity: 95%, 96%, 97%, 98%, 99%, 99.5%, 99.7%, 99.9%, 99.99%

※ Zirconia toughens alumina

※ Zirconia (ZrO2, Zirconia) thiab YSZ (Yttrium Stabilized Zirconia)

※ Silicon nitride (Si3N4) thiab Silicon carbide (SiC)

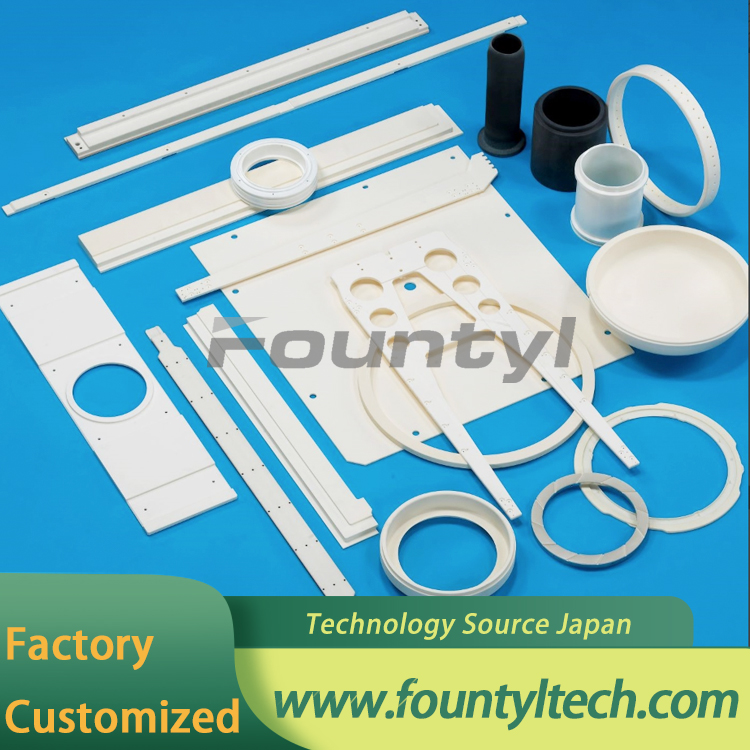

FOUNTYL Technologies PTE Ltd. muab cov khoom siv ceramic yog tsim los siv cov khoom siv ceramics siab heev kom tau raws li koj cov kev xav tau, suav nrog cov nplooj ntawv ceramic, raj, rods thiab kev cai ntawm ntau hom. Tsis paub tseeb tias cov ntaub ntawv twg tsim nyog rau koj daim ntawv thov? Nyem rau ntawm daim ntawv qhia saum toj no los saib lossis tiv tauj peb ncaj qha thiab peb yuav zoo siab pab.

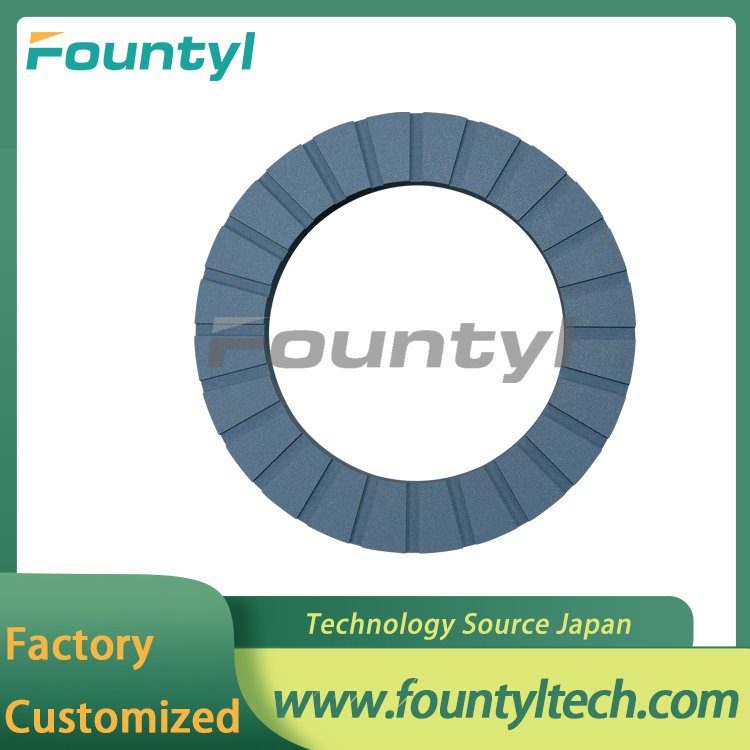

Ceramic caj npab nta

※ High hnav tsis kam

※ Zoo heev oxidation kuj thiab corrosion kuj

※ Tsawg thermal expansion

※ High durability

※ High hardness thiab nruj

※ Hluav taws xob rwb thaiv tsev

Peb pab cov neeg muas zaub nyob rau hauv lub ntiaj teb no semiconductor kev lag luam. Semiconductor ceramic Cheebtsam feem ntau tsis yog tus qauv thiab tuaj yeem tsim tau raws li cov neeg siv khoom xav tau.

Kev cai ntau lawm

Ceramic Arms / Claws / Ntiv:

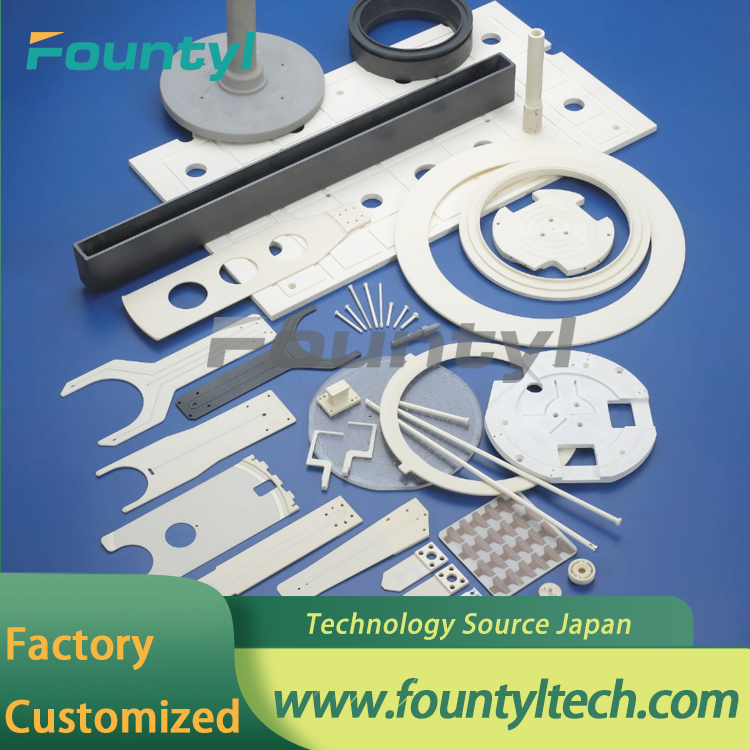

Cov khoom siv tshuaj lom neeg feem ntau siv rau hauv cov khoom siv hluav taws xob semiconductor, thiab cov khoom tsim los ntawm cov khoom siv hluav taws xob yuav tsum tau xa mus rau qhov chaw tom ntej rau kev ntxuav, thiab cov cuab yeej siv hluav taws xob yog cov khoom no. Txhawm rau kom tsis txhob muaj kev sib xyaw ntawm cov tshuaj siv tshuaj los cuam tshuam rau biochemical cov tshuaj tiv thaiv ntawm cov khoom siv tes tsho, ntau lub tuam txhab tau pib siv cov caj npab neeg hlau ua los ntawm ceramics. Lub caj npab robotic txheej txheem thiab txav cov semiconductor wafer ntawm ntau txoj haujlwm. Nws yog ib qho tseem ceeb ntawm tes neeg hlau, yog li nws yog ib qho tseem ceeb kom muaj thermal stability thiab seem stability thiab tsis tuaj yeem muaj cov khoom siv los yog cov tshuaj lom neeg uas ua rau lub chamber.

Hauv daim ntawv thov no, qee qhov txiaj ntsig tseem ceeb ntawm kev siv alumina oxide ceramics es tsis yog alumina hlau suav nrog kev nruj thiab lub zog siab, uas txhais tau hais tias lub caj npab neeg hlau tau tsau rau txoj haujlwm kawg sai dua li alumina. Tsis tas li ntawd, tus neeg hlau nws tus kheej txav nrawm dua, optimizing qhov chaw raug thiab txhim kho kev ua haujlwm. Hauv robotics, qhov kawg effector yog cov cuab yeej lossis cov khoom txuas nrog rau qhov kawg ntawm lub caj npab robotic. Cov qauv ntawm qhov kawg-effector thiab qhov xwm txheej ntawm lub khoos phis tawj tsav thiab kho vajtse nyob ntawm qhov kev npaj ua haujlwm.

Lub caj npab neeg hlau tsuas tuaj yeem hloov kho rau qee qhov kev ua haujlwm kawg nkaus yam tsis tau hloov pauv cov cuab yeej pabcuam thiab / lossis kev ua haujlwm. Piv txwv li, nws tsis tuaj yeem hloov lub gripper ncaj qha nrog lub hau ntswj me ntsis thiab cia siab tias yuav tau txais txiaj ntsig zoo. Nws yog tsim nyog los hloov lub programming ntawm tus neeg hlau maub los thiab siv cov txheej txheem sib txawv ntawm qhov kawg-effector motors los txhawb torque es tsis yog clamping quab yuam. Lub gripper tuaj yeem hloov nrog lub taub hau tsav tsheb.

Ceramic kawg effector Specifications:

Standard paddle thiab diav rawg tsim

Nqus thiab tsis nqus tsev vacuum

Kub kub kuj

Tshuaj tiv thaiv

Durable thiab txhim khu kev qha

Ceramic caj npab

Alias: Ceramic ntiv tes

Khoom siv: Alumina 99.5%

Xim: Dawb

Qhov siab: 0.01mm

Flatness: O.O5

Kev lag luam: Semiconductor / Solar wafers

Tsev

Tsev