I-Semiconductor ceramics - ukukhiqiza ngokwezifiso

Ukubuka konke kwengalo ye-Ceramic

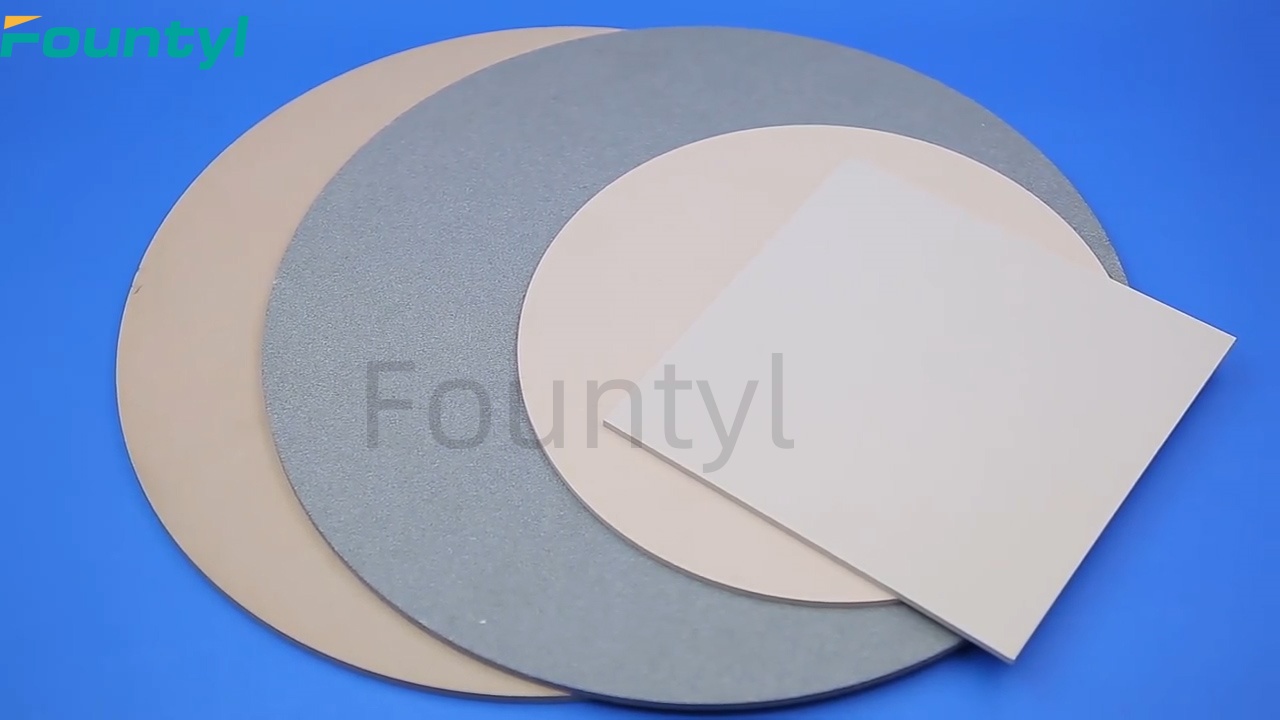

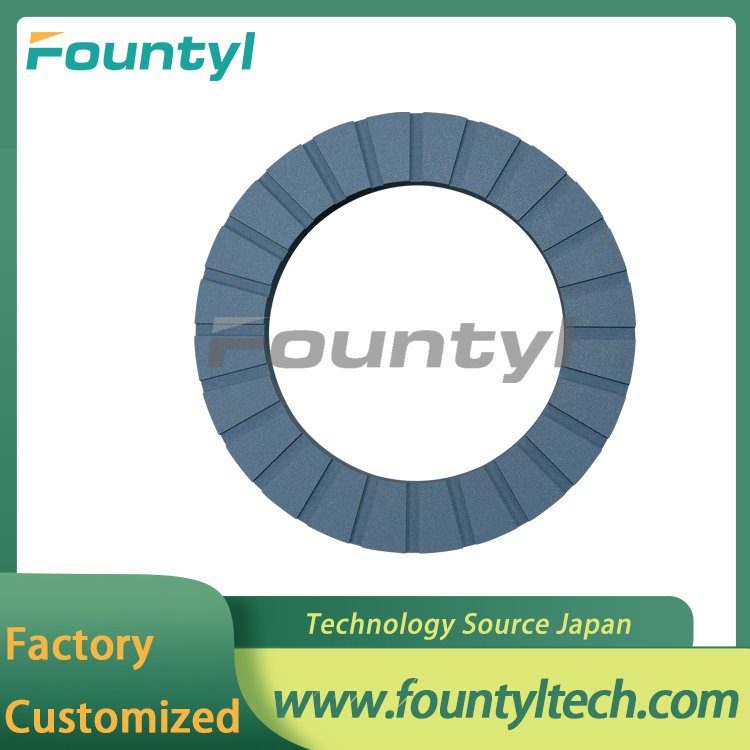

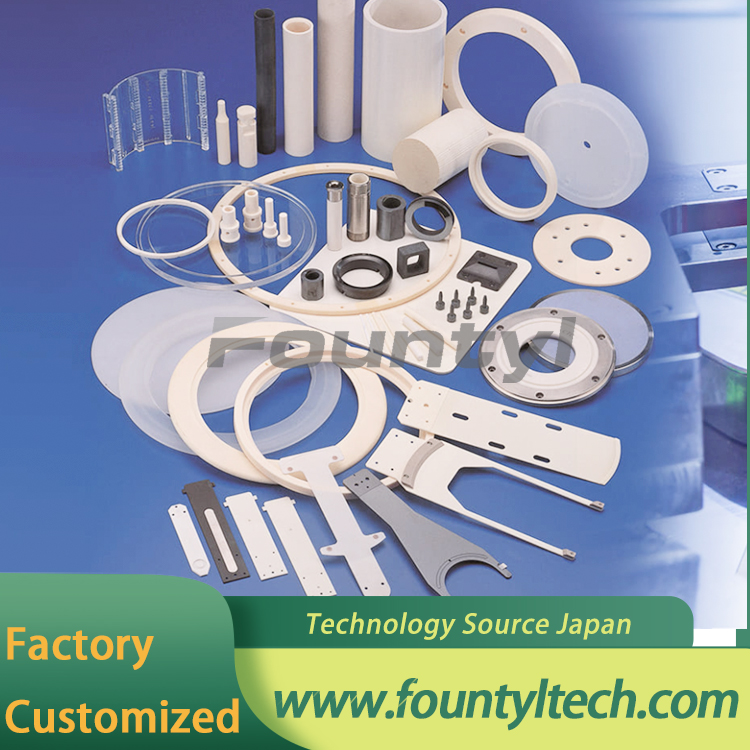

Ngenxa yesidingo sokunemba okuphezulu nokuqina enqubweni yokukhiqiza, imboni ye-semiconductor isebenzisa izinto zobuchwepheshe ezithuthukile ukukhiqiza izingxenye. Izitsha zobumba zobuchwepheshe ziyinketho ekahle ngenxa yokumelana kwazo nokugqokwa okuphezulu kanye ne-inertia yamakhemikhali, kanye nekhono lazo lokwenziwa ngomshini ngokunemba kakhulu ukuze kufezwe ukunemba okufunayo. Izingxenye ze-Ceramic semiconductor ezenziwe ngezitsha zobumba ze-alumina zikuvumela ukuthi ufinyelele izinga eliphezulu lengxenye futhi unikeze amakhasimende akho izingxenye ezisezingeni eliphezulu ze-semiconductor. Siyakwazi ukuzuza amazinga okulawula ukunemba ahamba phambili embonini: ukubekezelela ubuncane obungu-0.001mm kanye nobuncane bokugwedla kwendawo obungu-Ra 0.1μm. Ukuthintana kwendawo ephansi kunciphisa ingcuphe yokuba nomthelela ongemuhle we-wafer geometry.

Izinto ezitholakalayo

※ Izitsha zobumba ezihlangene/izimbotshana zobumba

※ I-Alumina (Al2O3 alumina), ubumsulwa :95%, 96%, 97%, 98%, 99%, 99.5%, 99.7%, 99.9%, 99.99%

※ I-Zirconia iqinisa i-alumina

※ I-Zirconia (ZrO2, Zirconia) kanye ne-YSZ(Yttrium Stabilized Zirconia)

※ I-Silicon nitride (Si3N4) ne-Silicon carbide (SiC)

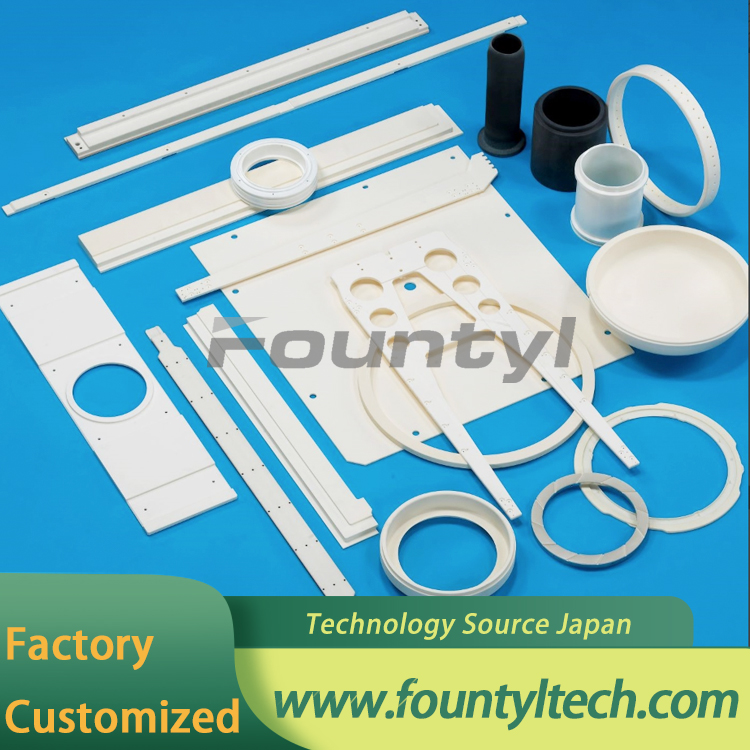

I-FOUNTYL Technologies PTE Ltd. inikeza izingxenye zobumba ezikhiqizwa kusetshenziswa izinto zobumba ezithuthukisiwe ukuze kuhlangatshezwane nezidingo zakho zohlelo lokusebenza, okuhlanganisa amashidi e-ceramic, amashubhu, izinduku kanye nezingxenye zangokwezifiso zezinhlobo ezihlukahlukene. Awuqinisekile ukuthi iyiphi into elungele isicelo sakho? Chofoza umhlahlandlela ongenhla ukuze ubuke noma uxhumane nathi ngokuqondile futhi sizokujabulela ukukusiza.

Izici zengalo ye-Ceramic

※ Ukumelana nokugqoka okuphezulu

※ Ukumelana ne-oxidation okuhle kakhulu nokumelana nokugqwala

※ Ukwanda okushisayo okuphansi

※ Ukuqina okuphezulu

※ Ubulukhuni obukhulu nokuqina

※ Ukufakwa kukagesi

Sisebenzela amakhasimende embonini ye-semiconductor yomhlaba wonke. Izingxenye ze-Semiconductor ceramic ngokuvamile azikho ezingeni futhi zingenziwa ngokuvumelana nezidingo zamakhasimende.

Ukukhiqizwa ngokwezifiso

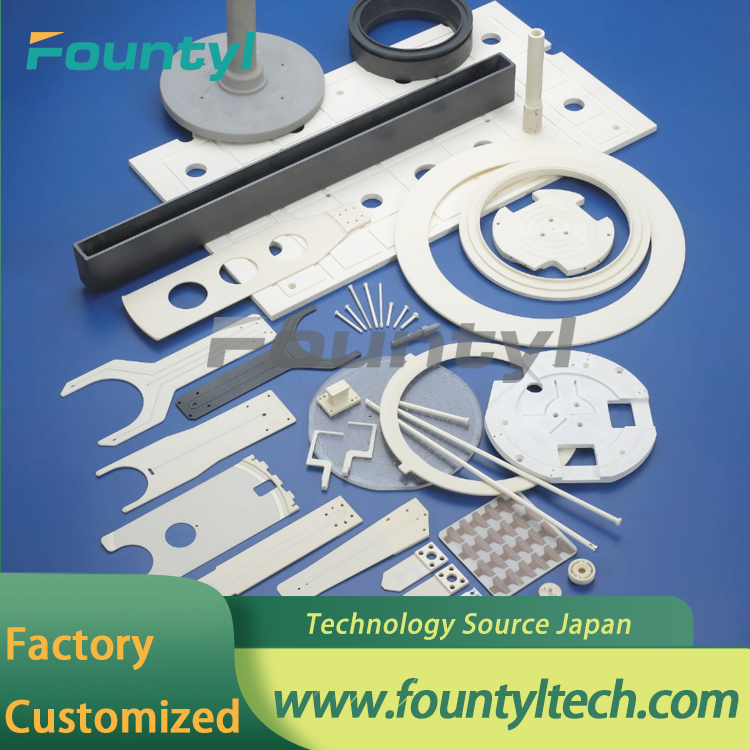

Izingalo/Izinzipho/Iminwe yeCeramic:

Imikhiqizo yamakhemikhali ivamise ukusetshenziswa ngaphakathi kwezinto zikagesi ze-semiconductor, futhi imikhiqizo ekhiqizwe imikhiqizo kagesi eyimishini kufanele ikwazi ukudluliselwa endaweni elandelayo ukuze ihlanzwe, futhi ingalo eyimishini yilo mkhiqizo. Ukuze kugwenywe inhlanganisela yezidakamizwa zamakhemikhali ukuphazamisa ukusabela kwe-biochemical yemikhiqizo yengalo yerobhothi, abakhiqizi abaningi sebeqalile ukusebenzisa izingalo zerobhothi ezenziwe ngezitsha zobumba. Ingalo yerobhothi icubungula futhi ihambisa iwafa ye-semiconductor phakathi kwezindawo ezihlukene. Ngokuyisisekelo yisandla serobhothi, ngakho-ke kubalulekile ukuthi ube nokuzinza kwe-thermal kanye nokuzinza kwe-dimensional futhi awukwazi ukuba nezinhlayiya noma ukungcola kwamakhemikhali okungcolisa igumbi.

Kulolu hlelo lokusebenza, ezinye zezinzuzo eziyinhloko zokusebenzisa i-alumina oxide ceramics kune-alumina metal zihlanganisa ukuqina namandla aphezulu, okusho ukuthi ingalo yerobhothi igxilwe endaweni yokugcina ngokushesha kakhulu kune-alumina. Ngaphezu kwalokho, irobhothi ngokwalo lihamba ngokushesha, lenza ukunemba kokuma futhi lithuthukise ukusebenza kahle. Kumarobhothi, isiphetho siyidivayisi noma ingxenye enamathiselwe ekugcineni kwengalo yerobhothi. Isakhiwo se-end-effector kanye nemvelo yohlelo lokushayela kanye nehadiwe kuncike emsebenzini ohlosiwe.

Ingalo yerobhothi ingashintshwa kuphela kwezinye izindlela zomsebenzi womphumela ngaphandle kokushintsha izingxenyekazi zekhompuyutha ezisizayo kanye/noma ukuhlela. Isibonelo, akunakwenzeka ukufaka esikhundleni se-gripper ngqo nge-screwdriver bit futhi ulindele ukuba nemiphumela emihle. Bekudingeka ukuguqula uhlelo lwesilawuli serobhothi futhi kusetshenziswe isethi ehlukile yamamotho angasebenzi ukuze kuthuthukiswe i-torque esikhundleni sokuphoqa amandla. I-gripper ingashintshwa ngomshayeli oyinhloko.

Imininingwane ye-Ceramic end effecter:

Idizayini evamile yokugwedla nemfoloko

I-vacuum futhi ayifuni

Ukumelana nokushisa okuphezulu

Ukumelana namakhemikhali

Okuhlala isikhathi eside futhi okuthembekile

Ingalo yobumba

Isibizo: Umunwe weCeramic

Indwangu: I-Alumina 99.5%

Umbala: Mhlophe

Ukubekezelela :0.01 mm

Ukucaba: O.O5

Imboni: Semiconductor/amawafa elanga

Ikhaya

Ikhaya