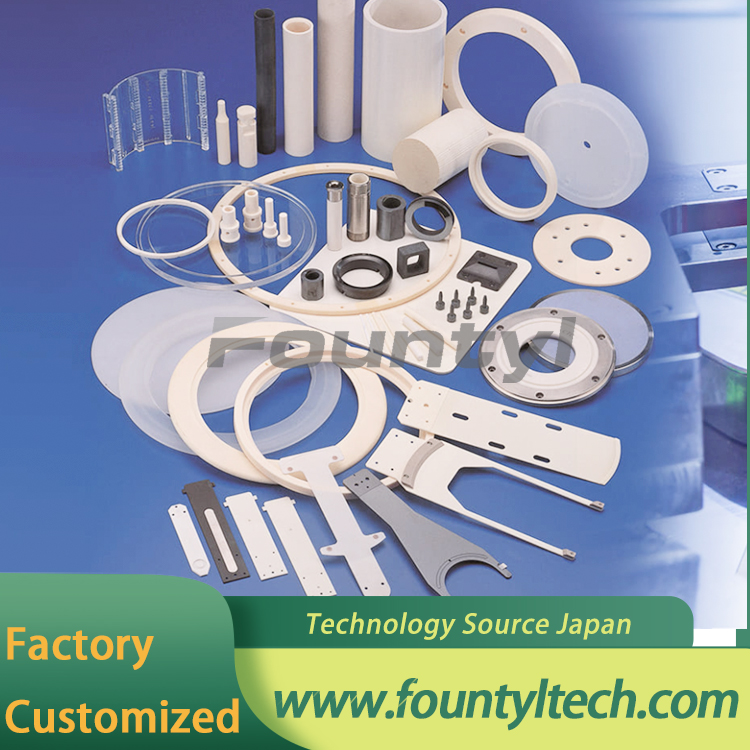

Semiconductor ceramics - custom manufacturing

Ceramic arm Overview

Due to the need for high precision and durability in the manufacturing process, the semiconductor industry uses advanced technical materials to produce the components. Technical ceramics are ideal choice because of their high wear resistance and chemical inertia, as well as their ability to be ultra-precision machined to achieve the desired precision. Ceramic semiconductor components made from alumina ceramics allow you to achieve superior part quality and provide your customers with the highest quality semiconductor parts. We are able to achieve industry-leading precision control levels: minimum tolerances of 0.001mm and minimum surface roughness of Ra 0.1μm. Low surface contact reduces the risk of negatively impacting wafer geometry.

Available material

※ Compact ceramics/porous ceramics

※ Alumina (Al2O3 alumina), purity :95%, 96%, 97%, 98%, 99%, 99.5%, 99.7%, 99.9%, 99.99%

※ Zirconia toughens alumina

※ Zirconia (ZrO2, Zirconia) and YSZ(Yttrium Stabilized Zirconia)

※ Silicon nitride (Si3N4) and Silicon carbide (SiC)

FOUNTYL Technologies PTE Ltd. offer the ceramic parts are produced using advanced technical ceramic materials to meet your application needs, including ceramic sheets, tubes, rods and custom parts of various forms. Not sure which material is right for your application? Click on the guide above to view or contact us directly and we'll be happy to help.

Ceramic arm features

※ High wear resistance

※ Excellent oxidation resistance and corrosion resistance

※ Low thermal expansion

※ High durability

※ High hardness and stiffness

※ Electrical insulation

We serve customers in the global semiconductor industry. Semiconductor ceramic components are usually non-standard and can be manufactured according to customer requirements.

Custom production

Ceramic Arms/Claws/Fingers:

Chemical products are often used inside semiconductor electrical appliances, and the products produced by mechanical electrical products must be able to be transferred to the next place for cleaning, and the mechanical arm is this product. In order to avoid the compound of chemical drugs to interfere with the biochemical reaction of robotic arm products, many manufacturers have begun to use the robotic arms made of ceramics. The robotic arm processes and moves the semiconductor wafer between different positions. It's basically a robotic hand, so it's important to have thermal stability and dimensional stability and can’t have particles or chemical contaminants contaminating the chamber.

In this application, some of the main advantages of using alumina oxide ceramics rather than alumina metal include stiffness and high strength, which means that the robotic arm is fixed to the final position more quickly than alumina. In addition, the robot itself moves faster, optimizing positioning accuracy and improving efficiency. In robotics, an end effector is a device or component attached to the end of a robotic arm. The structure of the end-effector and the nature of the drive programming and hardware depends on the intended task.

The robotic arm can only be adapted to some end-effector task modes without changing the auxiliary hardware and/or programming. For example, it is impossible to replace the gripper directly with a screwdriver bit and expect to have good results. It was necessary to change the programming of the robot controller and use a different set of end-effector motors to promote torque rather than clamping force. The gripper can then be replaced with a head driver.

Ceramic end effector Specifications:

Standard paddle and fork design

Vacuum and non-vacuum

High temperature resistance

Chemical resistance

Durable and reliable

Ceramic arm

Alias: Ceramic finger

Material: Alumina 99.5%

Color: White

Tolerance :0.01 mm

Flatness: O.O5

Industry: Semiconductor/Solar wafers