Ubuchwepheshe bokukhiqiza

Inqubo yokukhiqiza eqinile kanye nokukhiqizwa okunembayo okuphezulu & imishini yokuhlola ukuze kuqinisekiswe izinga eliphezulu lemikhiqizo.

Inqubo Yokucindezela Eyomile

Ukucindezela okomile kungenye yezinqubo zokubumba ezisetshenziswa kakhulu, izinzuzo eziyinhloko ukusebenza kahle kokubumba, ukuchezuka kosayizi omncane wemikhiqizo ebunjiwe, kulungele ikakhulukazi ukushuba kwengxenye encane yemikhiqizo yobumba, njenge-ceramic valve core, ipuleti le-ceramic, i-ceramic. ring...njll.

Inqubo Yokucindezela I-Isostatic Nezici

I-Isostatic Pressing Molding Inezinzuzo Ezilandelayo Ngaphezu Kokubunjwa Kokucindezela Kwensimbi:

I-Ceramic Sintering

I-Ceramic blank yakhiwa izinhlayiya eziningi eziqinile ngaphambi kokucwiliswa, kunenqwaba yezimbotshana emzimbeni, i-porosity ngokuvamile i-35% ~ 60% (okungukuthi, ukuminyana okuhlobene kokungenalutho kungu-40% ~ 65%), inani elithile lincike ezicini ze-powder ngokwayo kanye nendlela yokubumba kanye nobuchwepheshe obusetshenzisiwe. Lapho okungenalutho okuqinile kushisiswe ekushiseni okuphezulu, izinhlayiya ekudluliselweni okungenalutho, ngemva kokufinyelela izinga elithile lokushisa, okungenalutho kuyashwa, ukukhula okusanhlamvu kwenzeka, okuhambisana nokuqedwa kwama-pores, futhi ekugcineni okungenalutho kuba into eminyene ye-polycrystal ceramic. izinga lokushisa elingaphansi kwendawo yokuncibilika, le nqubo ibizwa ngokuthi i-sintering.

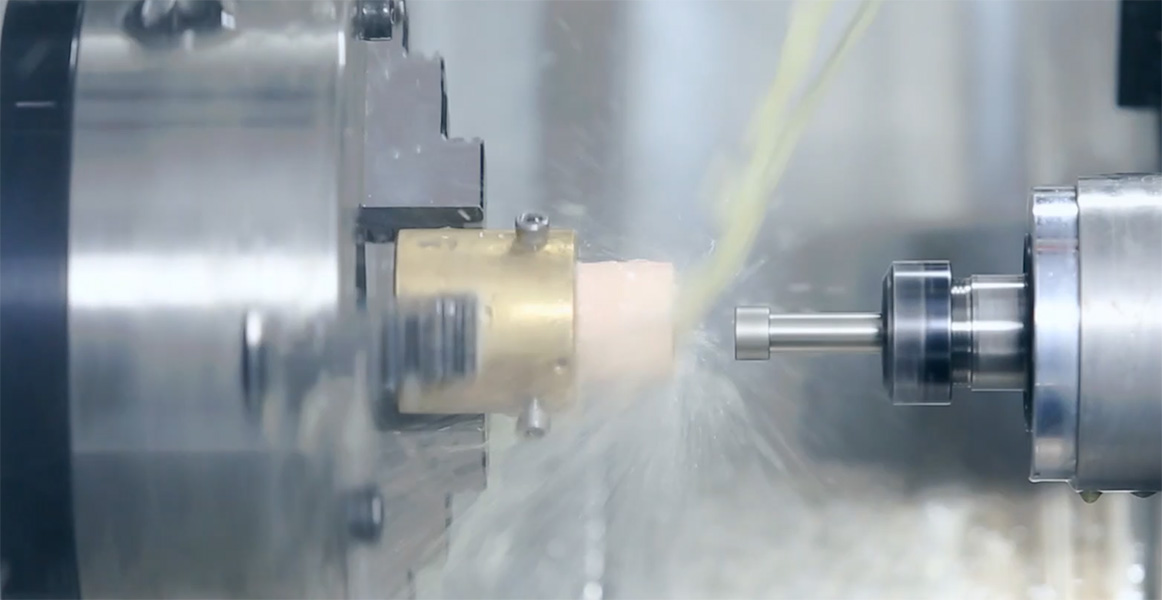

Ukugaya Okuyindilinga Kwangaphakathi Nangaphandle

Ukugaya okuyisiyingi kwangaphakathi nangaphandle (okubuye kwaziwe ngokuthi ukugaya okuphakathi) kusetshenziselwa ukugaya indawo eyindilinga yangaphandle kanye nehlombe le-workpiece. I-workpiece ifakwe phakathi nendawo futhi ijikeleziswa ngomshini obizwa ngokuthi umshayeli ophakathi. Amasondo okugaya nama-workpieces ajikeleziswa ngesivinini esihlukile ngama-motor ahlukene. Ukuma kokubopha komkhiqizo kungalungiswa nge-Engeli ukuze kukhiqizwe i-taper. Kunezinhlobo ezinhlanu zokugaya i-diameter yangaphandle (OD), ubukhulu bangaphakathi (ID) ukugaya, ukugaya nge-punch, ukugaya okuphakelayo kwe-creep feed kanye nokugaya okungenasikhungo.

Ukugaya Ububanzi Bangaphandle

Ukugaya ububanzi bangaphandle ukugaya endaweni engaphandle yento phakathi nendawo nendawo. Isikhungo siyiseli lokugcina elinephoyinti elivumela into ukuthi ijikeleze. Lapho isondo lokugaya lithinta into, isondo lokugaya nalo lizungeza ohlangothini olufanayo. Lokhu kusho ngempumelelo ukuthi lapho kuthintwa, izindawo ezimbili zizohamba zibheke ezinhlangothini eziphambene, okwenza umsebenzi uzinze futhi ungavimbeli kancane.

Ukugaya Ububanzi Bangaphakathi

Ukugaya ububanzi bangaphakathi ukugaya ngaphakathi kwento. Ububanzi besondo lokugaya buhlala buncane kunobubanzi bento. Into ibanjwe i-fixture, ebuye izunge into esendaweni. Njengokugaya kwedayamitha yangaphandle, isondo nento izungeza ibheke ezinhlangothini eziphambene ukuze isiqondiso sokuthintana sezindawo ezimbili lapho ukugaywa kwenzeka khona kuphambene.

Ukugaya Okuphansi

Ukugaya i-flat kuwumsebenzi ovame kakhulu wokugaya. Kuwubuchwepheshe bokucubungula obusebenzisa isondo lokugaya elijikelezayo ukuze kugaywe ingaphezulu lensimbi noma izinto ezingezona ezensimbi ukuze kukhishwe ungqimba lwe-oxide nokungcola okungaphezulu kwendawo yokusebenza, ukuze kwenziwe ubuso bayo bucwengeke kakhulu. I-grinder eyisicaba iyithuluzi lomshini elakhelwe ukuhlinzeka ngezindawo zokugaya ezinembile, noma ngabe usayizi obalulekile noma ukuqedwa kwendawo. Ukunemba okuqondile kwe-grinder flat kuncike ohlotsheni kanye nokusetshenziswa kwayo, ububanzi buyi-300mm yediski, ukunemba kwe-planimetric kungafinyelela ku-0.003mm. Usayizi omkhulu wokucubungula wokugaya flat: ubude 1600* ububanzi 800mm.

CNC

I-CNC Milling ibhekwa njengenye yemisebenzi esetshenziswa kakhulu ekukhiqizeni imishini. I-CNC Milling iwuhlobo lwethuluzi lomshini we-CNC elinomsebenzi oqinile wokucubungula, isikhungo sokukhanda esithuthuke ngokushesha, iyunithi yemishini eguquguqukayo, njll. kukhiqizwa ngesisekelo somshini wokugaya we-CNC kanye nomshini oyisidina we-CNC, zombili azihlukaniseki endleleni yokugaya, iningi lezimboni. imisebenzi yokugaya ingaqedwa 3-eksisi, 5-eksisi CNC amathuluzi omshini. Ngezinzuzo zokuguquguquka okuqinile, ukunemba okuphezulu kokucubungula, ikhwalithi yokucubungula ezinzile kanye nokusebenza kahle kokukhiqiza okuphezulu, lolu hlobo lokulawula indlela lungacubungula kuze kufike ku-80% wezingxenye zemishini. I-CNC inosayizi womshini omkhulu: ubude buyi-1300* ububanzi 800mm.

Inqubo Yokuhlanza Ingxenye Ye-Semiconductor

Ukuhlanza Okumanzi

Ukuhlanza okumanzi ukusetshenziswa kwezinyibilikisi zamakhemikhali noma amanzi angcolile ukuhlanza iwafa. Ukuhlanza okumanzi kungahlukaniswa ngendlela yokucwiliswa kanye nendlela yokufafaza ngokwendlela yenqubo, indlela yokucwilisa iwukucwilisa isinkwa esilucwecwana ethangini lesiqukathi esiqukethe i-solvent yamakhemikhali noma amanzi akhishwe yi-deionized. Indlela yokucwiliswa emanzini iyindlela esetshenziswa kakhulu, ikakhulukazi kwezinye izindawo ezivuthiwe. Ukufafaza, ngakolunye uhlangothi, kuhilela ukufafaza isincibilikisi sekhemikhali noma amanzi akhishwe esikhumbeni esiphendukayo ukuze kukhishwe ukungcola. Indlela yokucwilisa ingacubungula amawafa amaningi ngesikhathi esisodwa, futhi indlela yokufafaza ingacubungula iwafa eyodwa kuphela egumbini lokusebenza elilodwa ngesikhathi esisodwa. Ngokuthuthuka kwenqubo, izidingo zenqubo yokuhlanza ziya ngokuya ziba phezulu, futhi ukusetshenziswa kwendlela yokufafaza kuya ngokuya kuyanda.

Dry Cleaning

Njengoba igama liphakamisa, ukuhlanza okomile akukhona ukusetshenziswa kwamakhemikhali amakhemikhali noma amanzi angcolile, kodwa ukusetshenziswa kwegesi noma i-plasma ukuhlanza. Ngokuthuthuka okuqhubekayo kwamanode ezobuchwepheshe, izidingo zenqubo yokuhlanza ziya ngokuya ziba phezulu, ingxenye yokusetshenziswa nayo iyanda, futhi uketshezi olulahlwayo olukhiqizwa ukuhlanzwa okumanzi luphinde lube ukwanda okukhulu. Uma kuqhathaniswa nokuhlanza okumanzi, ukuhlanza okomile kunezindleko eziphezulu zokutshala izimali, ukusebenza kwemishini eyinkimbinkimbi kanye nezimo zokuhlanza ezinzima. Kodwa-ke, ukukhishwa kwamanye ama-organic compounds nama-nitrides, ama-oxides, ukunemba kokuhlanza okomile kuphezulu, umphumela muhle kakhulu.

Ukukala Okunembayo

Sinamakhono okucwaninga ngezinto ezibonakalayo, ukuthuthukiswa komkhiqizo, ukuklama, ukukhiqiza kanye nokuphathwa kwekhwalithi, futhi sinesethi egcwele yemishini yomshini nemishini yokuhlola enembayo: izixhumanisi ezintathu, imitha yokumahhadla, imitha ye-cocentricity, ithuluzi lokulinganisa ububanzi bangaphandle, imitha yesilinda yamathuluzi okuhlola ukunemba. Inqubo yokukhiqiza eqinile kanye nokukhiqizwa okunembayo okuphezulu & imishini yokuhlola ukuze kuqinisekiswe izinga eliphezulu lemikhiqizo.

I-DLC Coating

Amathebula e-wafer carrier/gripper asetshenziselwa ukuqukatha i-Si, i-SiC, i-GaAs, i-Gan, nezinye izicwecwe ze-semiconductor ezinqubweni ezihlukene ze-semiconductor, kusukela ekutholeni ukuya ku-lithography, nezinye izinhlelo zokusebenza ezidinga ukunemba okuphezulu, okuhlanganisa izindlu ezinkulu, izibonisi zephaneli elithambile elithambile. , MEMS, namaseli ezinto eziphilayo. Izembatho ze-DLC zinezinto eziningi ezifiselekayo, njengokumelana okuhlala isikhathi eside kanye ne-thermal conductivity ephezulu, ukukhulisa impilo yomkhiqizo, ukugcina ukunemba, nokunciphisa ukungqubuzana nokungcola. I-vacuum gripper inomzimba oqinile onezibambo eziningi ebusweni be-wafer noma iphaneli, futhi ukuchezuka kwe-flatness iyonke neyendawo ikalwa ngama-nanometers, kulokhu, inkinga ngokufaka i-DLC coating kuyo yonke indawo i-gripper iwukuthi ukungezwani kokwandisa okushisayo kungaholela ekulahlekelweni kwe-flatness.

I-Teflon™ fluoropolymer yokukhiqiza i-semiconductor

Ikhaya

Ikhaya