Ceramic structural parts (ceramic parts)

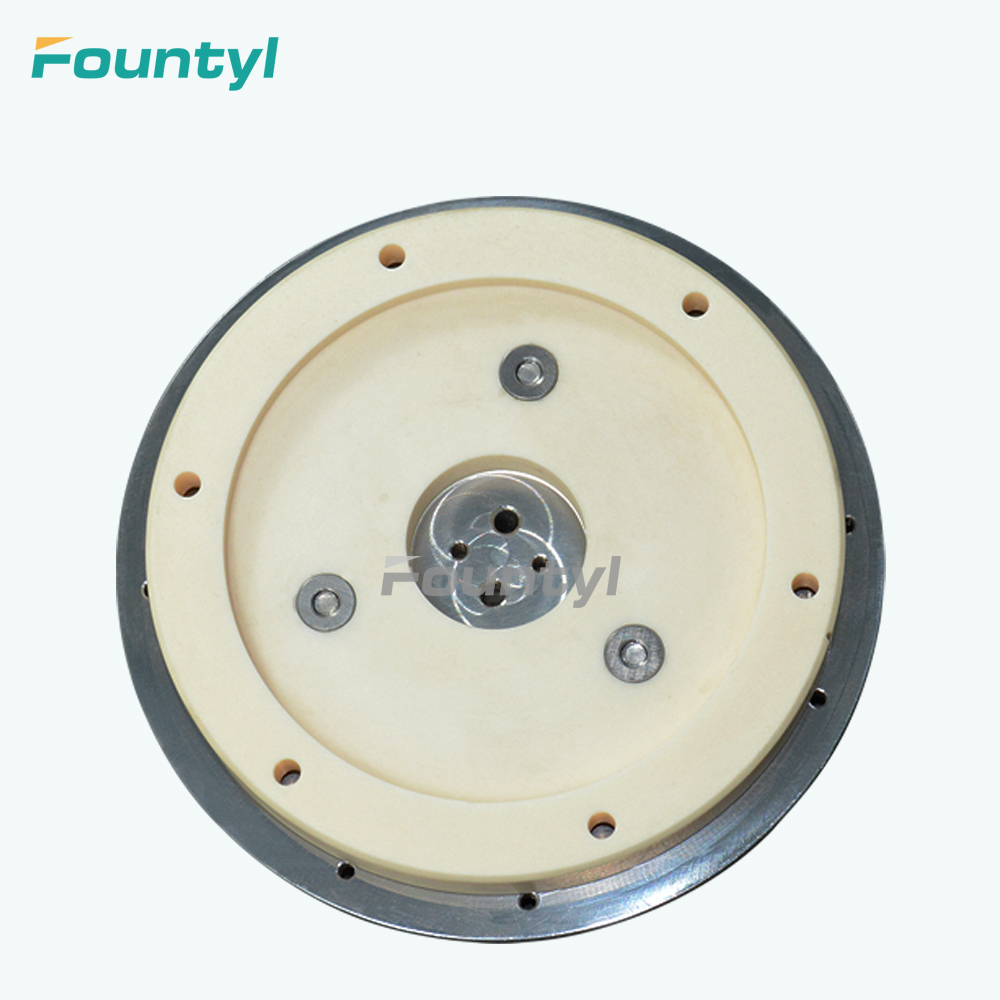

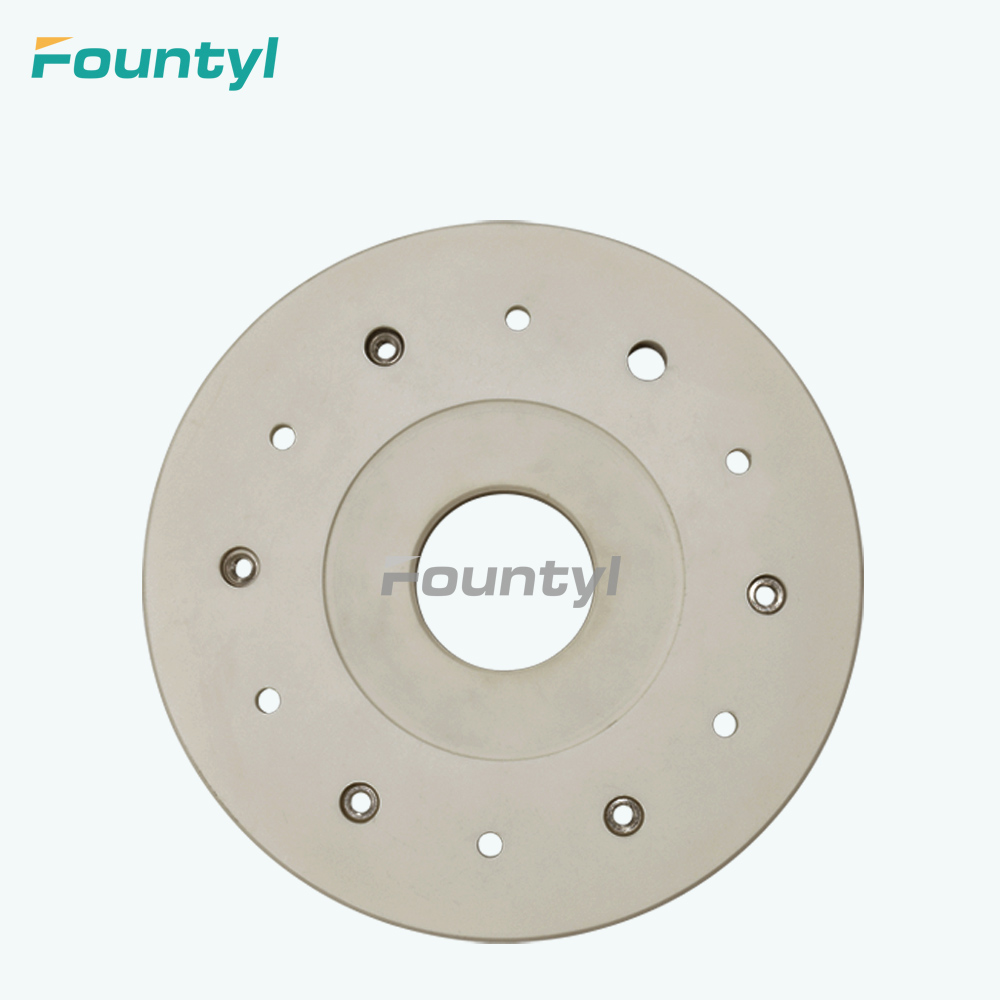

Fountyl has core competence, ceramic parts include ceramic tubes, ceramic rods, ceramic substrates, ceramic plates, ceramic positioning pins, ceramic plungers, ceramic pump valves of various ceramic structural parts, which are widely used in melting furnaces, semiconductors, aerospace, pump valves, new energy, fluid control fields, mechanical wear parts.

Structural ceramics are advanced ceramics with excellent mechanical, thermal and chemical properties in high temperature resistance, erosion resistance, corrosion resistance, high hardness, high strength, low creep rate, which are often used in various structural components.

Structural ceramics have superior strength, hardness, insulation, heat conduction, high temperature resistance, oxidation resistance, corrosion resistance, wear resistance, high temperature strength characteristics, therefore, in the very harsh environment or engineering application conditions, the high stability and excellent mechanical properties, in the material industry has attracted much attention, its range of use is also expanding. The requirement of high precision, high wear resistance, high reliability mechanical components for global and domestic industry being more and more strict, so the demand for ceramic products is quite important, its market growth rate is also quite considerable, in metallurgy, aerospace, energy, machinery, optics fields have important applications.

Our Specialty Structural Ceramics Include The Following Types

1. Silicon Nitride Ceramics

Silicon nitride ceramics is a new type of engineering ceramics, which is the difference from ordinary silicate ceramics that the combination of nitrogen and silicon in the former belongs to the combination of covalent bond properties, so it has the characteristics of strong binding force and good insulation.

The strength of silicon nitride is very high, the hardness is also very high, is one of the hardest substances in the world, its temperature resistance is good, the strength can be maintained to 1200°C without falling, until 1900°C will decompose, and it has amazing chemical corrosion resistance, but also a high-performance electrical insulation material, The overall performance of various kinds of silicon nitride ceramic products produced by microwave sintering process has reached the international advanced level.

2. Aluminium Nitride Ceramics

Theoretical thermal conductivity is 320W/m·k, about 80% of the thermal conductivity of copper, while aluminum nitride has low dielectric constant, high resistance, low density and close to the thermal expansion coefficient of silicon, the comprehensive performance is better than Al2O3, BeO, SiC ... etc., is used for high thermal conductivity insulator and electronic substrate materials. The company produces a variety of aluminum nitride ceramic products with densities bigger than 3.25, and thermal conductivity of 120 ~ 200W/m·K, Aluminum nitride ceramics can be produced in various specifications according to the requirement.

3. Alumina Ceramics

Alumina ceramics (artificial corundum) is a promising high temperature structural material. Its melting point is very high, can be used as high-grade refractory materials, such as crucible, high temperature furnace tube. Using the advantages of alumina hardness, it is possible to manufacture corundum grinding machines used in the laboratory to grind materials with less hardness than it. With high purity raw materials, the use of advanced technology, can also make alumina ceramics transparent, can produce high-pressure sodium lamp tubes.

4. Silicon Carbide Ceramics

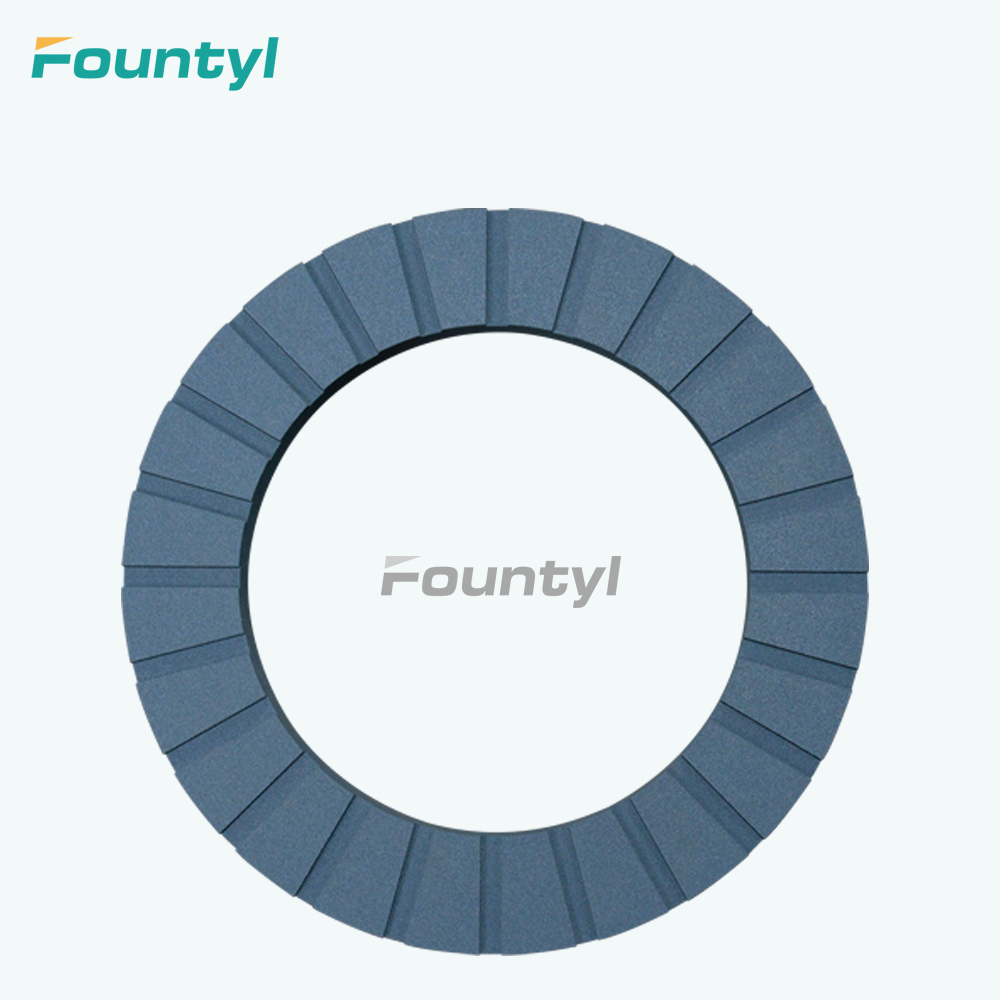

Silicon carbide ceramics is also an important structural material, it is a kind of superhard substance, small density, itself has lubricity, and wear resistance, in addition to hydrofluoric acid, it does not react with other inorganic acids, corrosion resistance; It also resists oxidation at high temperatures. Moreover, it can also resist cold and thermal shock, heated to more than 1000 in the air, sharply cooled and then sharply heated, and will not crumble. It is silicon nitride that has such good characteristics that it is often used to manufacture mechanical components such as bearings, turbine blades, mechanical sealing rings, and permanent molds.

5. Porous Ceramics

With a porosity of 35-40% and a pore size of 0.5-100um, it can be used for breathable or solid-liquid separation and gas separation. It is an advanced porous ceramic material.