An automated introduction to wafer handling and transfer

The wafer manufacturing industry is the industry with the highest degree of automation in all industrial manufacturing, and I personally believe that there is no one.

Why the degree of automation of wafer manufacturing can be so high, one is because the process requires high precision, high cleanliness, high reliability, manual participation can not meet these requirements. The second is money.

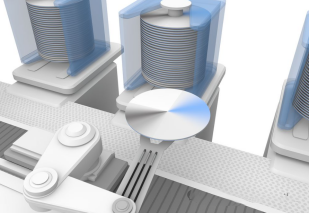

So what level of automation has wafer manufacturing reached? This paper gives a brief introduction to the most simple wafer handling.

Storage on a wafer

Wafers are stored using a standardized memory unit called a FOUP (Front Opening Unified Pod). This is a wafer storage box. This box is designed for automatic handling and is the basis for full automation.

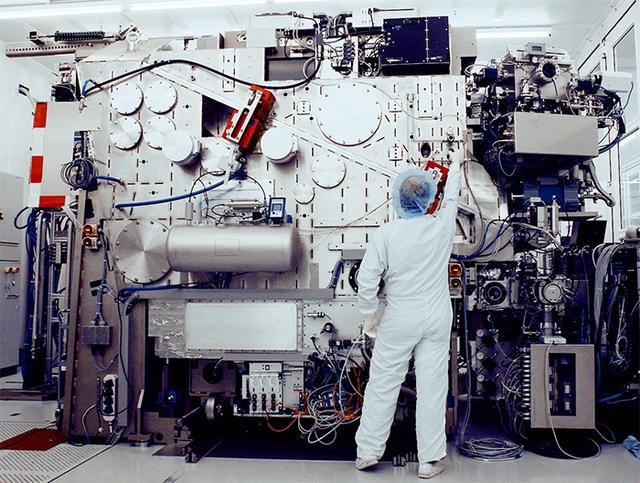

Automatic wafer handling system AMHS

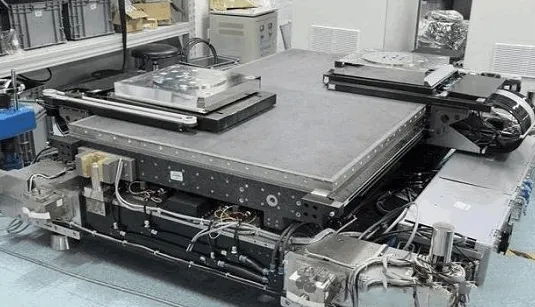

Automatic Material Handling System (AMHS) is the core of wafer handling. It is sometimes referred to as a crane system.

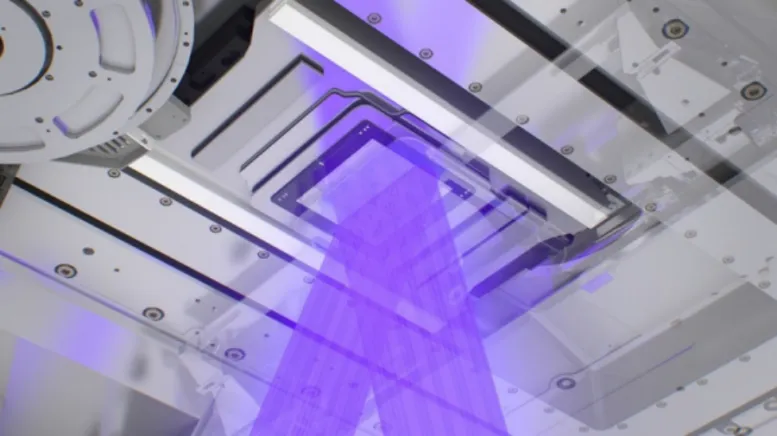

The crane is installed on the indoor ceiling rail, and many cranes operate efficiently on the rail under the deployment of the control system.

The main reason to run on the ceiling is to save space. Wafers produce so many devices that the crane is responsible for transferring materials between thousands of devices throughout the plant. A transmission rail on the ground might be comparable to a densely packed city street. The cost of clean room space is high.

Running on the ceiling of the crane, the freedom of running space is very large, fixed the position of the equipment, the crane can reach the top of the machine at any time.

The storage warehouse of the wafer is also set on the ceiling, and the crane is responsible for storing or taking out. In this way, as long as the production machine is placed on the ground, the machine can be densely discharged, as long as the maintenance staff can walk in.

The crane running on the sky rail is responsible for moving on the sky rail, and is also responsible for the grasp and lifting of the FOUP.

A variety of production equipment is designed with an extended platform to accept the crane lifted down the wafer box.

In the field of automatic wafer handling equipment (AMHS), the global market is currently dominated by Daifuku of Japan, Murata Machinery of Japan, SEMES of Samsung of South Korea and other companies, accounting for about 90% of the market share. Because the AMHS system has a global impact on the fab production line, customers are very cautious in their choice, and emerging domestic AMHS manufacturers need to go through a long verification process to enter the semiconductor field, requiring continuous breakthroughs from local, simple processes to overall, advanced processes.

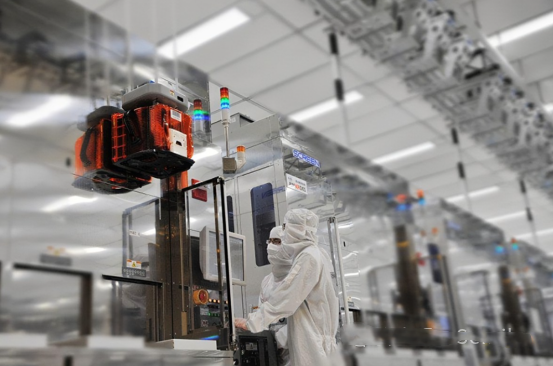

Wafer loading and Unloading (EFEM)

EFEM(Equipment Front End Module), the English is to describe this is a front and back end docking module, we from the user's point of view, is the wafer loading and unloading process.

Each functional device operates one wafer at a time. EFEM is responsible for taking wafers out of the box one by one and putting them into the equipment for processing. Finish processing and put back in pieces. The entire wafer transfer and processing process is carried out in a closed space with high cleanliness requirements, free from external contamination, and absolute protection of the wafer.

Wafer manufacturing process, the whole process is automated, has basically reached the level of unmanned workshop. However, engineers with higher technical ability are needed in the background for program control, parameter setting and equipment maintenance.

What is the level of automation in wafer manufacturing? Some professionals divide automation into five levels:

Level 0 |

Level 1 |

Level 2 |

Level 3 |

Level 4 |

Level 5 |

Non-automatic action |

movement support |

section automate |

Conditional automation |

Altitude automate |

Complete automation |

According to this level, the degree of automation of the wafer industry is at the level of 3-4. Of course, the level of each wafer manufacturer is different. Most other electronics manufacturing industries have an automation level of 2-3. The degree of automation still has a lot of room to develop.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!