Application of porous ceramic chuck

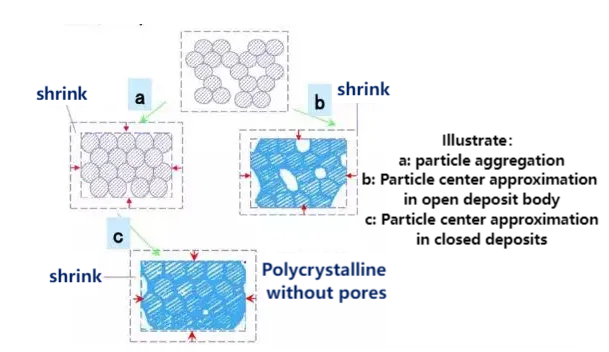

Porous ceramics chuck are also called nanoporous vacuum chuck, which refers to the uniform solid or vacuum sphere produced by a special nano powder manufacturing process, and a large number of connected or closed ceramic materials are generated inside the material through high temperature sintering. With its special structure, it has the advantages of high temperature resistance, wear resistance, chemical corrosion resistance, high mechanical strength, easy regeneration and excellent thermal shock resistance...etc. It can be used for high temperature filtration materials, catalyst carriers, porous electrodes for fuel cells, sensitive components, separation membranes, bioceramics...etc.

The type of product: ceramic plunger, ceramic pump core, ceramic valve core, ceramic piston, ceramic bushing, ceramic chuck, microporous ceramics...etc.

Materials: Alumina, zirconia, silicon nitride, silicon carbide. It has unique application advantages in chemical industry, environmental protection, energy, electronics, biochemistry fields.

Founty Microporous vacuum chuck can be used with Japanese, German, Israeli, American and domestic equipment, with very superior product performance and good one-to-one service.

At present, only NGK and TDK of Japan, CERVER of France, Corning of the United States, Fairey Industrial Ceramics Company of Ukraine, and Otkunmingk of Finland can develop and produce high-end micropore 1~15um chuck, among which NGK of Japan has invested hundreds of millions of yuan to establish a production factory in Suzhou New Area; the American filter company has become the largest inorganic ceramic separation membrane and equipment supplier, and the ceramic vacuum disc filter produced by the Finnish Otto Kunmingk company has been used in more than 100 countries. The self-cleaning high temperature ceramic filter produced by Anguil Environmental Systems Inc. uses ceramic filtration and catalytic purification technology, and more than 20,000 sets of high temperature gas filtration devices have been applied in various fields.

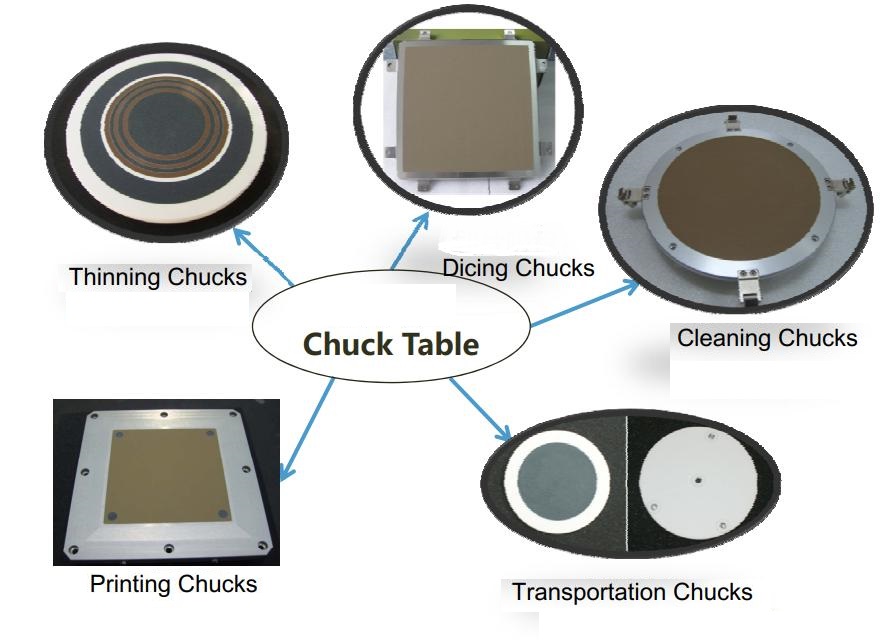

Applications of Fountyl porous ceramics are as follows:

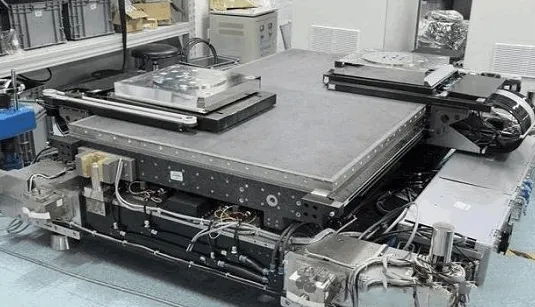

1,Flexible display test platform

Promote the integration and operational performance of the device, and create a new pattern of new electronic devices in the device's lightweight, pull-up, folding, drop resistance and impact resistance. Based on the advantages of flexible electronic technology and simple and unique production process

2,Metal solution filtration technology

Porous ceramics have the characteristics of large filtration area and high filtration efficiency, which can effectively remove the inclusions and impurities in the alloy, eliminate casting defects, and greatly improve the mechanical properties of the alloy

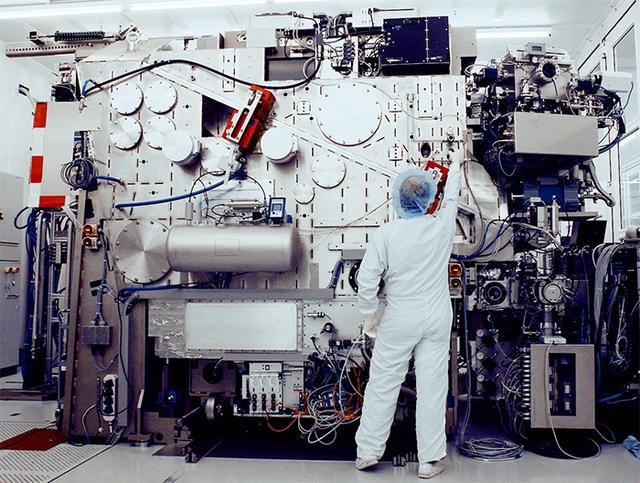

4,6,8 inch ceramic vacuum chuck, suitable for laser scribing machine, semiconductor industry, LED silicon wafer processing.

Scribing machine vacuum chuck, silicon vacuum chuck, the dimensional range: 2, 3, 4, 5, 6, 8, 12 inches, matching machine tools: thinning machine, scribing machine, cleaning machine...etc.