How are wafers stored and shipped?

What are the special requirements for the storage and transportation of wafers after they have completed all the processes in the fab? Do special environmental packaging be required?

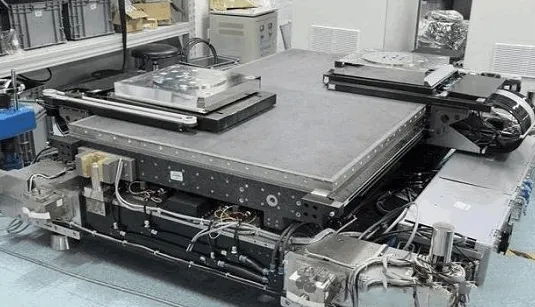

Storage is generally placed in the nitrogen gas cabinet, the nitrogen gas cabinet has high purity nitrogen, and the nitrogen gas cabinet can control the humidity and temperature, the humidity is 20-24 ° C, the humidity is 30%-50%, depending on the site situation. Transportation generally requires placing the wafer in the wafer box, the wafer box will be placed in an anti-static bag, the bag will be vacuumed, and then the bag containing the wafer box will be placed in the box, the box will be protected by cushion materials such as cushions, of course, these are completed in the dust-free workshop. If conditions exist, nitrogen can also be created in the transport vehicle to control the temperature and humidity environment. Others such as labels must be attached for easy tracking. What are the factors to pay attention to in wafer storage and transportation?

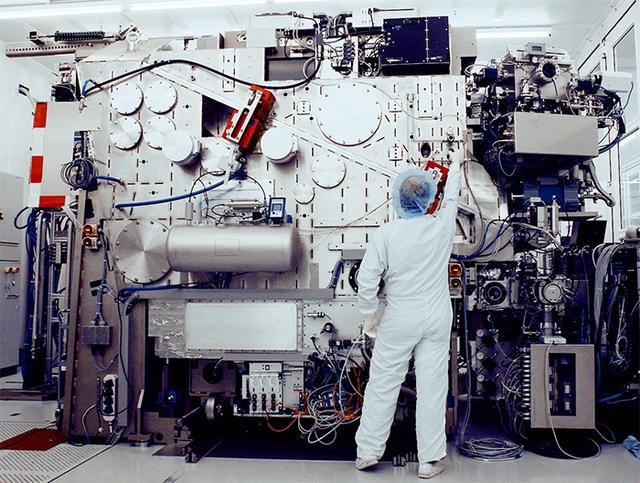

Cleanliness: Any gases or particles that could contaminate the wafer should be avoided, so be vacuumed or in high purity nitrogen.

Temperature and humidity: Extreme temperature changes can cause changes in the wafer material, while too high humidity causes the wafer surface to absorb water, while too low humidity increases the accumulation of electrostatic charge.

Physical protection: the wafer needs to prevent collision and pressure during transportation, and it is easy to break the wafer by external force, so it needs to be packed with buffer materials.

Static electricity: Electrostatic discharge will burn chips. Therefore, use anti-static packaging materials and perform anti-static treatment on wafers during packaging.

FOUNTYL TECHNOLOGIES PTE. LTD. is a modern enterprise in the field of advanced ceramics set R&D, manufacturing and sales as one, mainly produces porous ceramics, alumina, zirconia, silicon nitride, silicon carbide, aluminum nitride, microwave dielectric ceramics and other advanced ceramic materials. our specially invited Japanese technology expert have more than 30 years of industry experience in semiconductor field, efficiently provide special ceramic application solutions with wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity, insulation for domestic and foreign customers.