How can the semiconductor industry contribute to the goal of "green and low-carbon"?

Carbon peaking and carbon neutrality have become a global concern. The Outline of the Strategic Plan for Expanding domestic Demand (2022-2035) issued by The State Council recently mentioned in many places that we should "vigorously advocate green and low-carbon consumption, and promote the high-end, intelligent and green development of the manufacturing industry." The development of semiconductor technology is an important driving force for building a green and low-carbon society. At the same time, the semiconductor industry itself is actively achieving green and low-carbon, and is an active practitioner of the strategic goal of carbon neutrality.

We invited Jean-Louis CHAMPSEIX, Vice President and Head of Corporate Sustainability at ST, to talk about how the semiconductor industry can contribute to the country's "green and low-carbon" goals.

1. In what ways can integrated circuit technology (such as 5G, edge computing, power semiconductors, etc.) contribute to the green and low-carbon development of the social economy? What is the focus of the company in low-carbon green development? ST research and development products are designed to create a sustainable world and conduct research and development activities in a sustainable way. We believe that technology has a key role to play in helping the world solve its environmental and social challenges. Therefore, we are optimistic about the development of "responsible products" because these products can improve people's quality of life or user experience, while minimizing environmental impact.

For many years, ST has focused on electric vehicles, power & Energy, and Internet of Things & connectivity, which contribute to the development of smart cities, smart buildings, and smart industries. Our efforts include enabling renewable energy and smart grid applications and making better use of renewable energy and smart grid. These are our main growth areas, allowing us to maintain steady growth throughout the market cycle.

2. Wide bandgap semiconductors are generally considered to have the advantage of saving energy and power. Under the overall social advocacy of low-carbon green development, how to expect its prospects? Does the company have plans to invest in wide band gap semiconductors?

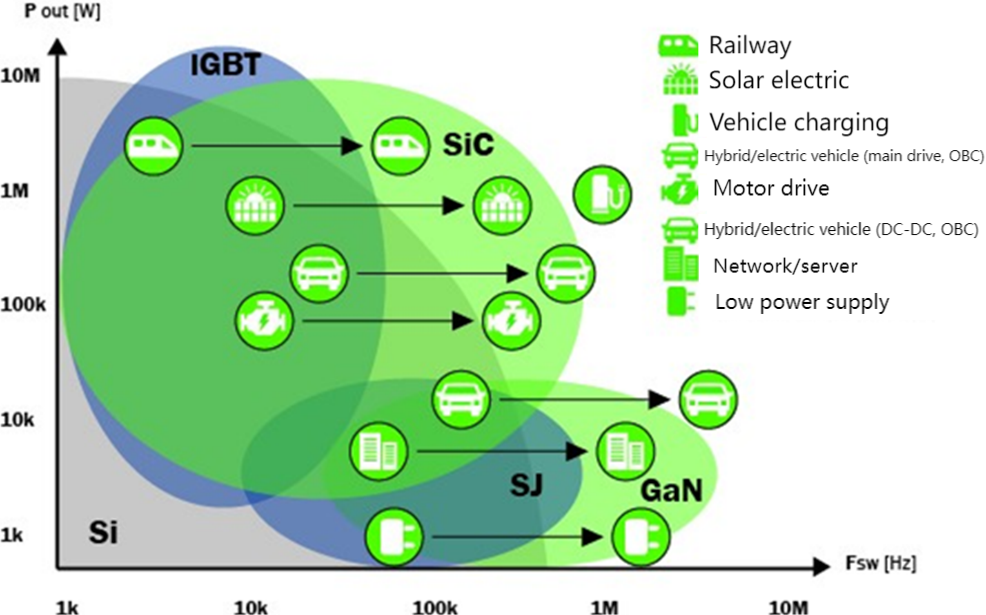

St offers a wide range of power semiconductor products, including high-performance silicon devices and the latest wide band gap technologies, to meet the energy efficiency requirements of renewable energy applications. At the heart of our portfolio is the replacement of silicon with silicon carbide, taking advantage of the innovative properties of new wide bandgap semiconductors. These semiconductor devices can achieve energy efficiency that was previously impossible with silicon semiconductors. In fact, for 25 years, ST has been at the forefront of SiC technology development. Compared to previous silicon-based technologies, ST's wide-band gap devices can halve switching losses, minimizing energy waste. Less loss equals less heat, a smaller radiator, or even no radiator. As a result, silicon carbide also reduces the size and weight of the final product, thereby reducing installation costs by approximately 50%.

As low-carbon actions continue to unfold, the market demand for renewable energy and supporting infrastructure is increasing. In this ongoing transformation, the semiconductor industry is demonstrating the importance of semiconductors to the emerging clean energy economy and is inspiring developers to innovate and develop safe, scalable, and reliable energy solutions.

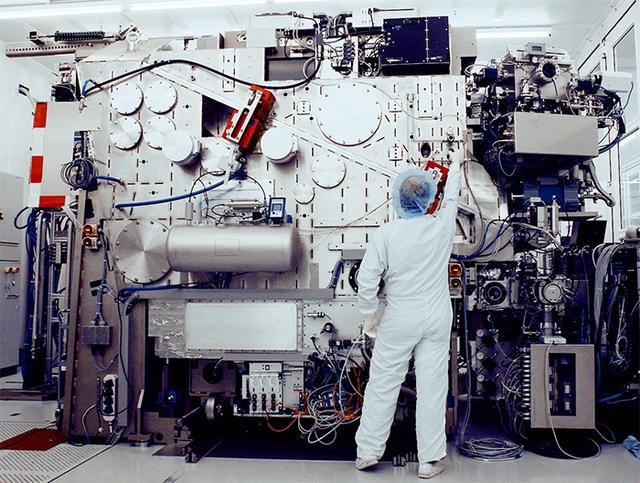

After several years of research and development of silicon carbide technology, ST introduced the first SiC diode in 2004, the SiC MOSFET transistor in 2009, and began mass production in 2014. Today, ST is well known for its rich range of medium and high voltage SiC power products. St is actively expanding production capacity, developing a complete, reliable and robust SiC supply chain to meet growing market demand, and ensuring product supply continuity through a product life extension program.

St manufactures SiC products to the highest standards to enhance the reliable performance and energy efficiency of electric vehicles (EVs), solar inverters, energy storage, industrial motors and power supplies. Our technology exceeds standards for industrial and automotive applications and is expected to move into more demanding aerospace applications.

By working in silicon carbide technology for many years, we are able to provide industry-leading silicon carbide MOSFETs and diodes for industrial and automotive applications. With voltage ratings up to 650V or 1200V, depending on the model, these devices target applications with high voltage power and can withstand the highest junction temperatures of 200ºC available on the market today. However, developing these industry-changing components has been far from straightforward.

In short, silicon carbide has many advantages in automotive applications: reducing the weight of the vehicle, increasing the driving range (after using silicon carbide, the driving range is >600 km); Because the silicon carbide charging station doubles the power processing capacity (SiC fast charge: 350 Kw), the charging time can be reduced from 16 minutes to 7 minutes.

3. At present, the integrated circuit industry has entered a downward cycle. Will the country's promotion of low-carbon green development help pull the integrated circuit industry out of the trough?

It must help. China's greening resonates with ST's efforts to help chip makers provide low-carbon solutions. By enabling the electrification of vehicles and the associated supporting infrastructure, ST is helping the world shift from traditional fuel vehicles to smarter, greener mobility solutions. St's automotive electrification solutions enable automakers to build better, more economical electric vehicles that enable drivers to reduce air pollution and mitigate global climate change.

The second key driver in favour of low-carbon has to do with energy, especially renewables. We help the world transition to greener energy by developing high-power, energy-efficient power devices using wide-gap semiconductor technologies such as silicon carbide (SiC) and gallium nitride (GaN) to reduce energy conversion losses in solar panels, wind turbines and smart grids.

4. In recent years, more and more integrated circuit companies have actively practiced green development, such as achieving green and energy saving in the chip manufacturing process, and low energy consumption in enterprise data centers. How much potential can the integrated circuit industry tap in the green and low-carbon development? What are the company's development plans in this area?

The semiconductor industry as a whole has long been committed to minimizing the environmental impact of its operations and manufacturing processes in particular. There are two main aspects to the semiconductor industry's carbon reduction actions: direct emissions from the use of perfluorinated gases (PFCS) and indirect emissions from the consumption of energy, mainly electricity (Scope 2 of the GHG Agreement). In both areas, ST has long been at the forefront of the industry. Since 1994, we have been actively addressing these challenges. Specifically, we have installed exhaust emission reduction systems in all pre-production plants to minimize PFC emissions through technical means. St's efforts have been recognized by industry peers and it has chaired the World Semiconductor Council's PFC Emission Reduction Working Group for more than 15 years.

We have also paved the way for the semiconductor industry to use renewable electricity, increasing the proportion of green electricity used year by year. In 2022, 62% of our electricity consumption will come from renewable sources. We are committed to becoming carbon neutral by 2027 and, as an element of our commitment to carbon neutrality, are on track to meet 80% of our electricity demand from renewables by 2025 and 100% by 2027. We believe that our overall action plan can eliminate all possible emissions and will use other means to offset the remaining emissions. St will be carbon neutral by 2027, confirming our claim to be a sustainability leader.

FOUNTYL TECHNOLOGIES PTE. LTD. is a modern enterprise in the field of advanced ceramics set R&D, manufacturing and sales as one, mainly produces porous ceramics, alumina, zirconia, silicon nitride, silicon carbide, aluminum nitride, microwave dielectric ceramics and other advanced ceramic materials. our specially invited Japanese technology expert have more than 30 years of industry experience in semiconductor field, efficiently provide special ceramic application solutions with wear resistance, corrosion resistance, high temperature resistance, high thermal conductivity, insulation for domestic and foreign customers.