What important equipment is required for advanced packaging?

Advanced packaging is no longer the future of advanced technology, has begun industrial application, advanced packaging production line has been built and put into production, advanced packaging products have been a lot of applications.

In the production line of advanced packaging, you can see a lot of important equipment in advanced packaging, which is not exactly the same as the equipment in the production line of traditional packaging technology.

What are the important devices in advanced packaging?

The important equipment required for advanced packaging is more complex than that of traditional packaging, because advanced packaging needs to encapsulate more chips inside, with higher accuracy, more complex actions, faster speed, and higher quality requirements. And advanced packaging requires more advanced packaging materials.

In the production line of advanced packaging, cleaning machines, gluing equipment, etching \ lithography machine, ball planting machine, wire Bond machine, chip bonding machine (Die Bond), melt welding, testing equipment and so on. The following is an introduction to the main types of equipment.

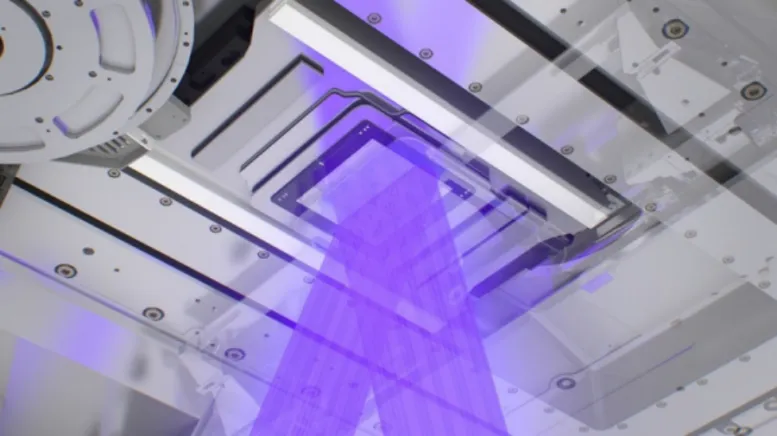

1、Cleaning machine

The cleaning of the parts in contact with the chip, the requirements for dust and oil are absolutely strict, and some also have to measure the volatile gases on the surface of the parts, and measure the affinity of the surface to different substances. To meet these requirements, the requirements for the cleaning process are often very complex. A cleaning line is also more than a dozen, dozens of processes, the parts for physical, chemical, biological level cleaning and drying.

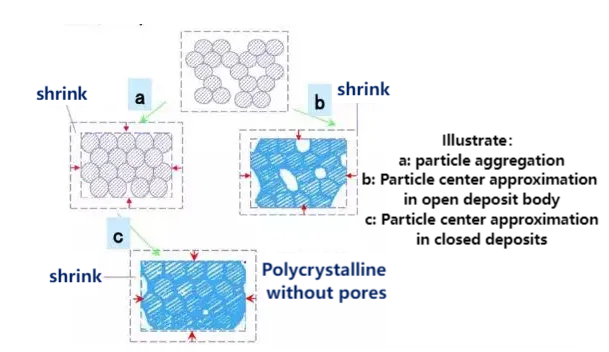

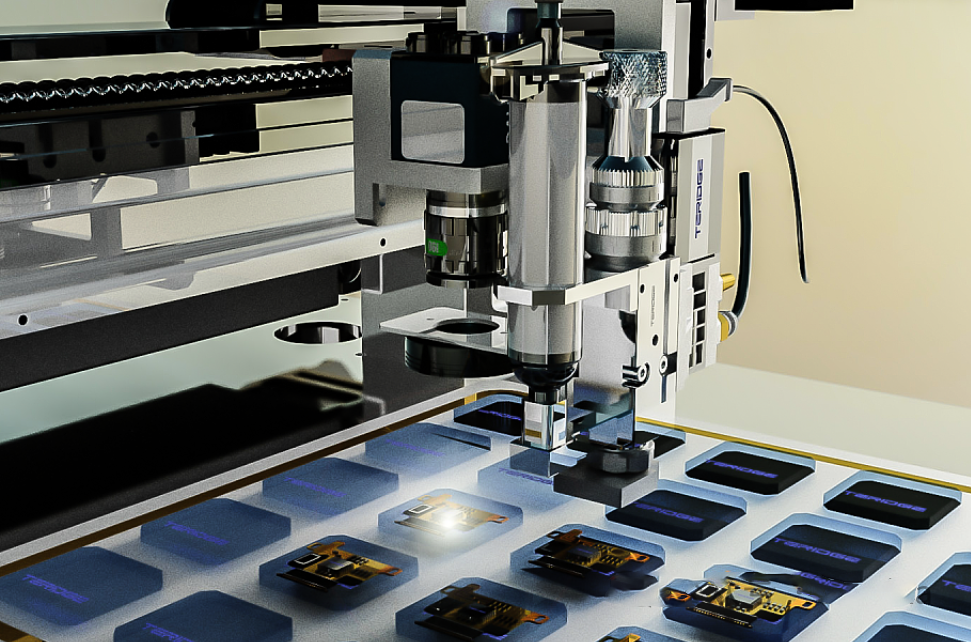

2、Gluing equipment

The glue of the packaging stage, the first role is to bond the different parts of the IC, the second role is to fill the gap between the various parts of the IC, and the third role is to protect the IC package. This basically forms three categories, one is dispensing, the second is filling, and the third is plastic sealing (Moding).

Chip dispensing

Chip backfill

Chip hermeticity in plastic

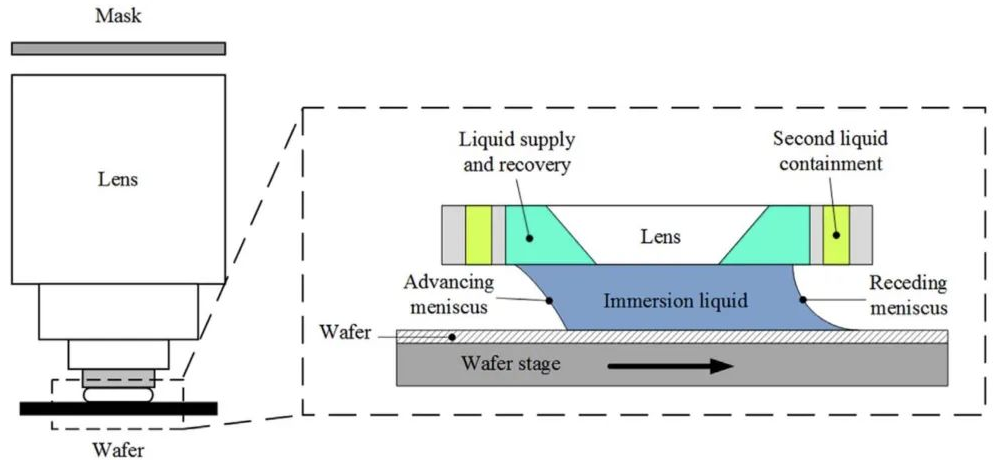

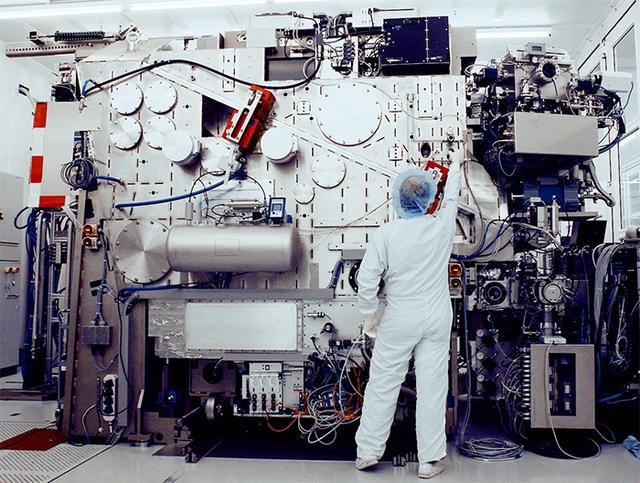

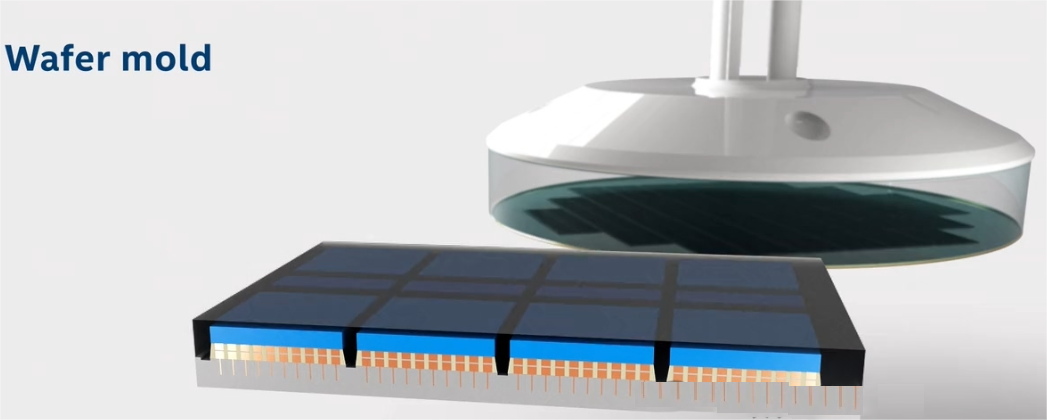

3、Etching/Lithography machine

Lithography machine is used to etch chip circuits at the wafer level. The packaging process also requires the use of a lithography machine, which requires the production of a package template for positioning and accurately positioning the chip. The lithography machine can be used to produce micron-scale patterns for these encapsulated templates. The photolithographic machine transfers the pattern precisely to the package template by exposing the photoresist and developing it. The line width requirements of the lithography machine used in the packaging process are relatively low, and generally 500nm can be used.

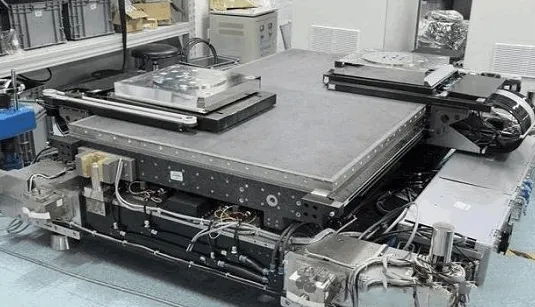

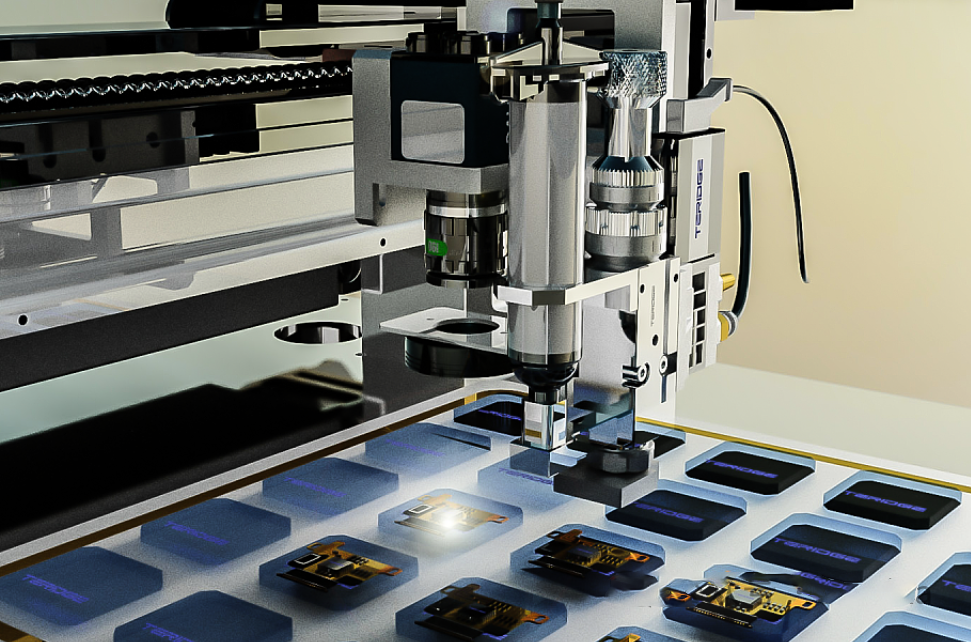

4、Chip bonding machine

The chip bonding machine is a device that connects the chip to the substrate in two main ways, Wire Bond and Die Bond. A Wire Bond device, often referred to as a wire binding machine, is a device that uses metal leads to connect pins on the IC to pins on the Substrate.

There are many other equipment for packaging applications, such as cutting machines, sorters, reflow welding, pressing machines, hot presses, curing furnaces, ion cleaning machines, marking machines, etc. There is also a very important type of equipment, that is, detection equipment. Testing equipment includes functional testing, appearance testing, performance testing, size measurement, etc. Many locations should be inspected and tested in the production to ensure the quality of the product.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!