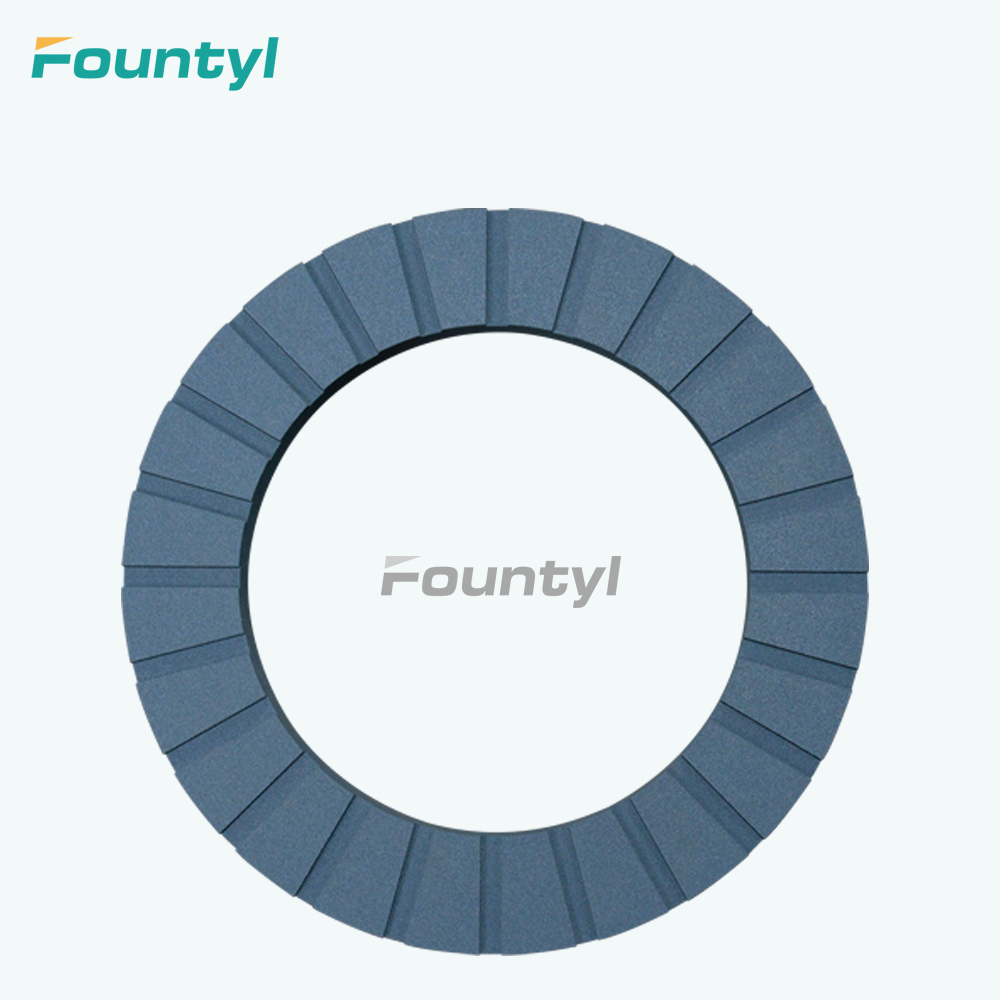

Optimize Your Sic Manufacturing Process for Improved Efficiency

- Applications Of Ceramics In Engineering Manufacturer

- Applications Of Ceramics In Engineering Manufacturers

- Applications Of Ceramics In Engineering Exporter

- Applications Of Ceramics In Engineering Exporters

- Applications Of Ceramics In Engineering Service

- Applied Ceramic Manufacturer

- Applied Ceramic Manufacturers

- Applied Ceramic Exporter

- Applied Ceramic Exporters

- Applied Ceramic Service