What are the methods of precision ceramic processing?

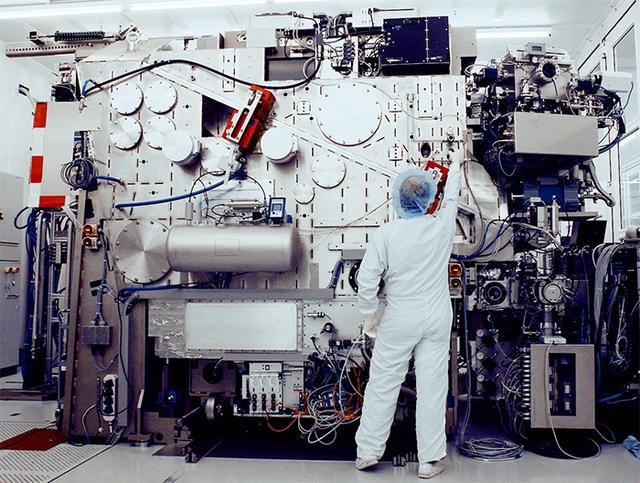

Precision ceramic materials have different processing methods according to different performance requirements. At present, the main processing methods of FOUNTYL Technologies PTE Ltd. include mechanical processing, electrical processing, supersonic processing, laser processing and composite processing. The following is a brief introduction to the machining methods of precision ceramics.

Ceramic material machining mainly includes turning processing, grinding processing, drilling processing, grinding and polishing.

1. Turning processing of ceramic materials

Turning processing is mainly used to cut ceramic materials with high hardness and high wear resistance with diamond cutter. Polycrystalline diamond tool is difficult to produce smooth cutting edge, generally only used for rough machining; When the precision turning of the ceramic material, the natural single crystal diamond tool is used, and the micro-cutting method is adopted during the cutting. Because of the hardness and brittleness of ceramic materials are very large, it is difficult to ensure the accuracy requirements by the turning processing, so the application of turning processing is not much, and basically it is still in the research stage.

2 Grinding of ceramic materials

Grinding processing of ceramic materials is one of the most widely used machining methods. The grinding wheel used for grinding is generally a diamond wheel. Different scholars have different explanations for the grinding mechanism of diamond wheel, but in general, there is one thing in common, that is, brittle fracture is the main reason for the removal of formed materials. In grinding processing, the removal of chips is a big problem, and it is generally cleaned with cooling working fluid. The coolant not only plays the role of washing the chip powder, but also reduces the temperature of the grinding zone, improves the grinding quality, and reduces the thermal decomposition of the binder around the grinding particle. Grinding fluids with good cleaning performance and low viscosity are generally selected. Diamond grinding wheel has different grinding characteristics because of the different types of selected bond and the different particle concentration. Diamond particle size is another main reason that affects the surface quality of ceramic workpiece. The larger the particle, the greater the roughness of the machined surface, but the higher the processing efficiency.

3. Drilling processing of ceramic materials

Cutting drill is often used in ceramic material drilling. The structure of the cutting drill is a ring diamond wheel welded to a hollow steel pipe, and the welding process is silver welding. When drilling the ceramic material, the diamond grinding wheel rotates at high speed and uses the diamond abrasive grain at the end face to cut the material.

4. Grinding and polishing

In some areas of industrial production, the surface finish requirements of ceramic parts cannot be reached by grinding alone, and grinding and polishing are usually used. On the other hand, ceramic materials are less tenacity and greater brittle, and the strength is easily affected by surface cracks. The rougher the machined surface is, the bigger the surface crack is, the easier it is to produce stress concentration and the lower the workpiece strength. Therefore, grinding is not only to achieve a certain roughness and high shape accuracy, but also to improve the strength of the workpiece. Polishing is a finishing process in which a soft polisher and fine powder are applied to the workpiece at a low pressure.