Detailed classification of ceramic materials

Ceramic materials refer to a class of inorganic non-metallic materials made of natural or synthetic compounds by forming and sintering at high temperature. It has the advantages of high melting point, high hardness, high wear resistance and oxidation resistance. Can be used as structural materials, tool materials, because ceramics also have some special properties, but also as a functional material.

1,Property

Mechanical property

Ceramic materials are the materials with the best stiffness and highest hardness in engineering materials, and their hardness is mostly above 1500HV. The compressive strength of ceramics is high, but the tensile strength is low, and the plasticity and toughness are poor.

Thermal properties

Ceramic materials generally have a high melting point (mostly above 2000℃), and have excellent chemical stability at high temperatures; The thermal conductivity of ceramics is lower than that of metal materials, and ceramics are also good thermal insulation materials. At the same time, the coefficient of linear expansion of ceramics is lower than that of metals, and the ceramics have good dimensional stability when the temperature changes.

Electrical characteristics

Most ceramics have good electrical insulation, so they are widely used to make insulating devices with various voltages (1kV~110kV). Ferroelectric ceramics (barium titanate BaTiO3) has a high dielectric constant, can be used to make capacitors, ferroelectric ceramics under the action of external electric fields, can also change the shape, the electrical energy into mechanical energy (with the characteristics of piezoelectric materials), can be used as a power amplifier, record player, ultrasonic meter, sonar, medical spectrometer, etc. A few ceramics also have the characteristics of semiconductors and can be used as rectifiers.

Chemical characteristics

Ceramic materials are not easy to oxidize at high temperatures, and have good corrosion resistance to acids, alkalis and salts.

Optical property

Ceramic materials also have unique optical properties, which can be used as solid laser materials, optical fiber materials, optical storage, etc., and transparent ceramics can be used for high-pressure sodium lamps. Magnetic ceramics (ferrites such as MgFe2O4, CuFe2O4, Fe3O4) have a wide range of applications in recording tape, record, transformer core, large computer memory components.

2,Historical development

The original ceramics is a general name for pottery and porcelain. That is, the formed sintered body obtained by molding and high temperature sintering. Traditional ceramic materials mainly refer to silicaluminate. At the beginning, people did not have high requirements for the selection of silicoaluminate, the purity was not high, the particle size was not uniform, and the molding pressure was not high. The resulting ceramics are called traditional ceramics. Later developed to high purity, small and uniform particle size, high molding pressure, sintering obtained sintered body called fine ceramics.

3,Classification:

Ordinary materials

They are made of natural raw materials such as feldspar, clay and quartz sintered, is a typical silicate material, the main components are silicon, aluminum, oxygen, these three elements account for 90% of the total crustal elements, ordinary ceramics are rich in sources, low cost, mature process. Such ceramics can be divided into daily ceramics, building ceramics, electrical insulation ceramics, chemical ceramics and so on according to their performance characteristics and uses.

Special materials

They are made of high-purity synthetic raw materials, formed and sintered by precision control process, and generally have some special properties to meet various needs. According to its main components, there are oxide ceramics, nitride ceramics, carbide ceramics, cermet and so on; Special ceramics have special mechanical, optical, acoustic, electrical, magnetic, thermal and other properties.

Classification of special materials

According to different uses, special ceramic materials can be divided into structural ceramics, tool ceramics, functional ceramics.

Structural ceramics

Alumina ceramics are mainly composed of Al2O3, and the general content is greater than 45%. Alumina ceramics have various excellent properties. High temperature resistance, generally can be used for a long time at 1600 ° C, corrosion resistance, high strength, its strength is 2 to 3 times that of ordinary ceramics, and the highest can reach 5 to 6 times. Its disadvantage is that it is brittle and cannot accept sudden changes in ambient temperature. It can be used as crucible, engine spark plug, high temperature refractory material, thermocouple casing, sealing ring, etc., and can also be used as tool and mold.

The main component of silicon nitride ceramics is Si3N4, which is a kind of high temperature strength, high hardness, wear resistance, corrosion resistance and self-lubricating high temperature ceramics, linear expansion coefficient is the smallest in various ceramics, the use temperature is as high as 1400℃, with excellent corrosion resistance, in addition to hydrofluoric acid, resistant to other acids corrosion, and alkali, corrosion of various metals. And has excellent electrical insulation and radiation resistance. It can be used as high temperature bearings, sealing rings for use in corrosive media, thermocouple bushings, and metal cutting tools.

The main component of silicon carbide ceramics is SiC, which is a kind of high strength, high hardness of high temperature ceramics, 1200℃~1400℃ can still maintain high bending strength, is the highest high temperature strength of ceramics, silicon carbide ceramics also have good thermal conductivity, oxidation resistance, electrical conductivity and high impact toughness. It is a good high-temperature structural material, which can be used for rocket nozzle nozzle, thermocouple sleeve, furnace tube and other parts working at high temperature. The thermal conductivity can be used to make heat exchange materials at high temperatures; Use its high hardness and wear resistance to make grinding wheels, abrasives and so on.

Hexagonal boron nitride ceramics are mainly composed of BN, the crystal structure is hexagonal crystal system, hexagonal boron nitride structure and performance are similar to graphite, so it is called "white stone ink", low hardness, can be cut with self-lubricating, can be made of self-lubricating high-temperature bearings, glass forming molds.

Tool ceramics

The main components of cemented carbide are carbides and binders, carbides are mainly WC, TiC, TaC, NbC, VC, etc., and the binder is mainly cobalt (Co). Compared with tool steel, cemented carbide has high hardness (up to 87~91HRA), good thermal hardness (about 1000℃ excellent wear resistance), when used as a tool, the cutting speed is increased by 4~7 times than high-speed steel, and the life is increased by 5~8 times, its disadvantage is that the hardness is too high, brittle, it is difficult to be machined, so it is often made of blades and welded on the tool bar. Carbide is mainly used for machining tools; Various molds, including drawing die, drawing die, cold heading die; Various kinds of drill bits are used in mining tools, geology and petroleum.

Diamond Natural diamond (diamond) as a valuable decoration, and synthetic diamond is widely used in industry, diamond is the hardest material in nature, but also has a very high elastic modulus; The thermal conductivity of diamond is the highest among known materials; Diamond has good insulation properties. Diamond can be used as drill, cutting tool, grinding tool, wire drawing die, dressing tool; Diamond tools for ultra-precision machining to achieve mirror finish. However, the thermal stability of diamond tools is poor, and the affinity of iron group elements is large, so it can not be used for processing iron, nickel-based alloys, and the main processing of non-ferrous metals and non-metals, widely used in ceramics, glass, stone, concrete, gems, agate and other processing.

Cubic boron nitride (CBN) has a cubic crystal structure, its hardness is high, second only to diamond, with thermal stability and chemical stability better than diamond, can be used for hardening steel, wear-resistant cast iron, thermal spray materials and nickel and other difficult materials cutting processing. Can be made into cutting tools, abrasives, drawing die, etc

Other tool ceramics are alumina, zirconia, silicon nitride and other ceramics, but from the comprehensive performance and engineering application are not as good as the above three tool ceramics.

Functional ceramics

Functional ceramics usually have special physical properties, involving more fields, commonly used functional ceramics are dielectric ceramics, optical ceramics, magnetic ceramics, semiconductor ceramics.

Fine ceramics

Fine ceramics have emerged in ceramic materials, which lead the world of new materials with excellent properties such as high temperature resistance, super strength and multi-function. Fine ceramics refers to high performance ceramics sintered by precision control process using refined high purity synthetic inorganic compounds as raw materials, so it is also known as advanced ceramics or new ceramics. There are many kinds of fine ceramics, which can be roughly divided into three categories - structural ceramics, electronic ceramics and bioceramics.

Structural ceramics

This ceramic is mainly used to make structural parts. Some seals, bearings, tools, ball valves, cylinder liners, etc. in the mechanical industry are frequently subjected to friction and easy to wear parts, with metal and alloy manufacturing is sometimes not used for a long time will be damaged, and advanced structural ceramic parts can withstand this "ordeal".

Electronic ceramics

Functional ceramics used for the production of electronic components and structural components of electronic systems. In addition to mechanical properties such as high hardness, these ceramics can be "indifferent" to changes in the surrounding environment, that is, they have excellent stability, which is a very important performance for electronic components, and can withstand high temperatures.

Bioceramic

Bioceramics are ceramic materials used to manufacture the human "bone-muscle" system to repair or replace human organs or tissues.

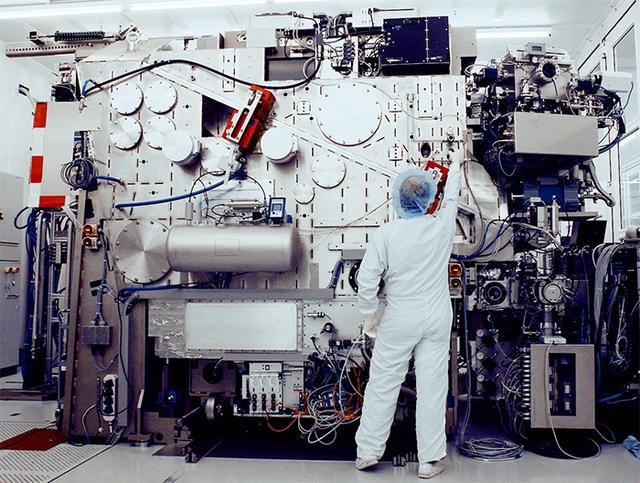

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!