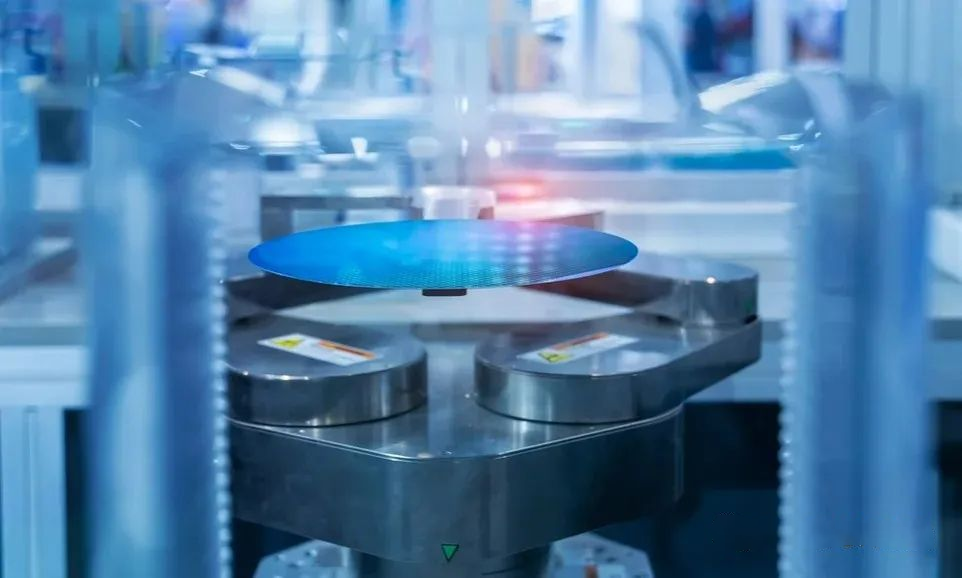

A necessary element in chip manufacturing - vacuum

Vacuum is very important in semiconductor manufacturing, in the semiconductor industry, the vacuum environment is used in various processes, It includes Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and Atomic Layer Deposition (Atomic Layer Deposition). ALD, Ion Implantation, Plasma Etching, and so on.

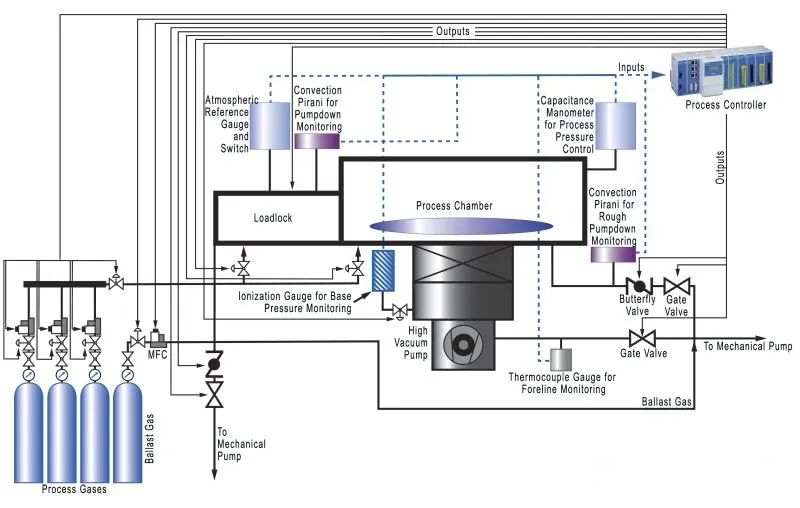

Definition of vacuum "vacuum" means any pressure that is lower than the atmosphere. In a vacuum, the number of molecules in a gas is so small that interactions between substances are extremely rare in a given space. The degree of vacuum (i.e. pressure) can vary from low vacuum to ultra-high vacuum, where the lower the pressure, the closer the vacuum is to complete vacuum. Vacuum systems are a way to ensure tight control of low pressure and sanitary conditions. The vacuum pump vacuums the gas in the interior to reduce the pressure to the required level.

Once all atmospheric gases are removed, specialty gases such as nitrogen, argon, and helium are introduced. The inertness of these gases means that they provide a clean environment for semiconductor processing and prevent unnecessary chemical reactions, thus increasing production efficiency. Productivity can be further improved by recovering and recycling higher grade gases (i.e. Argon, helium).

Classification of vacuum

Although collectively referred to as vacuum, it is also divided into several categories. Low vacuum 100 kPa ~ 100 Pa, low vacuum usually refers to those pressures slightly below atmospheric pressure, but still have a large number of gas molecules present environment. In such an environment, collisions between gas molecules are still the main physical process. In the vacuum of 100 Pa to 0.1 Pa, in this pressure range, the collision between gas molecules and the container wall becomes more frequent than the collision between gas molecules. This means that the behavior of a gas in a medium vacuum environment begins to behave differently from that of an ideal gas. In the middle vacuum, some of the more complex physical processes, such as the ionization of gas molecules and the formation of plasmas, may become more important. The medium vacuum environment has applications in many fields of science and engineering, including materials science (such as thin film deposition and etching), electron microscopy, and some high-precision measurement devices (such as mass spectrometers).

High vacuum 0.1Pa ~ 10-⁵ Pa In a high vacuum environment, the collision between gas molecules and the container wall is far more frequent than the collision between gas molecules, and gas molecules can fly freely in the container for a long distance between the average collision. High vacuum has a wide range of applications, including in physics research (such as particle accelerators and quantum experiments), semiconductor manufacturing, and astronomy (such as space telescopes and space probes). The maintenance and measurement of high vacuum environments requires specialized equipment and technology, including high vacuum pumps and high vacuum pressure gauges. In such an environment, the gas molecules are very sparse, and the collision between molecules and the container wall is far greater than the collision between molecules. The maintenance and measurement of ultra-high vacuum requires special technology and equipment, including special vacuum pumps and pressure gauges. In addition, materials and equipment in ultra-high vacuum environments usually require special cleaning and treatment to reduce gas adsorption and release, so as to achieve and maintain ultra-high vacuum conditions. Ultra-high vacuum environments can be used to precisely control and measure the properties of substances at very low pressures and densities.

A unit of pressure for a vacuum

1. PASCAL (Pa) : This is the unit of pressure in the International System of Units (SI), where 1 PASCAL is equal to 1 Newton per square meter (N/m²). In vacuum science, decimal units of PASCAL are commonly used, such as kilopascals (kPa), milipascals (mPa), or microparas (uPa).

2. Millimeter of mercury (mmHg) : This unit is based on the principle of a mercury manometer, and 1 mm of mercury is equal to approximately 133.322 pascals.

3. Torr: This unit is named in honor of physicist Torricelli, and one torr is equal to one millimeter of mercury.

4. Standard Atmospheric Pressure (atm) : This is a non-SI unit where 1 standard atmospheric pressure is equal to 101325 pascals, or approximately 760 mm Hg.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!