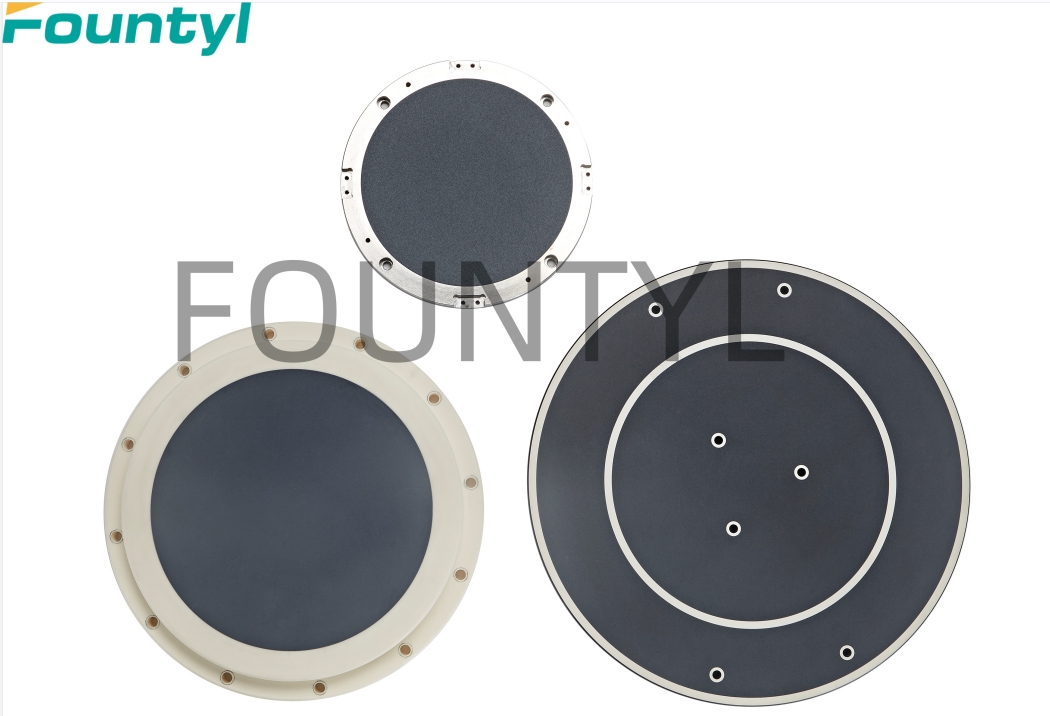

Application of porous ceramic vacuum chuck

Our ceramic chucks take full advantage of the properties of porous ceramics. Porous ceramics are formed by continuous holes connected from the inside to the surface, like a sponge. Traditional solutions are machined using air slots or holes formed by channels. This leads to problems such as film distortion and thin products being sucked into grooves or holes. our porous ceramics have micron-scale holes throughout the surface and can even adhere to fix the object without deformation.

Product features:

● Special shape, not easy to absorb solution

● Area adsorption: workpieces in different sizes can be adsorbed on the same ceramic area

● High heat resistance: high temperature sintered products, high temperature resistance

● Chemical resistance: acid and alkali resistance

● Lightweight: Due to the internal structure of uniform pores, the specific gravity is about 1.6~2.8

● High insulation performance: It is an insulating material that can disperse static electricity.

● No dust: completely sintered, no dust

Fountyl Technologies PTE Ltd handles the production of ceramic chucks from material to processing and is able to support a wide range of options.

Regular applications of porous ceramic vacuum chucks:

1. Thinning chuck

2. Cutting chuck

3. Cleaning chuck

4. Transport chuck

5, printing chuck

6, custom available

Product features of ceramic chuck include:

1. High flatness and parallelism

2, compact and uniform structure, high strength

3, good permeability and uniform adsorption affinity

4, long service life

5, easy to repair

6, the same type of vacuum chuck table

Common specifications for Fountyl ceramic chuck:

- Porous ceramics are made of alumina and silicon carbide in colors including white, light brown, dark brown, blue-gray

- Regular sizes in 6 ", 8 ", 12 ", and round, square, oval or irregular shapes and sizes.

- Aperture includes 0.7um, 10um, 30um, 50um, 100um.

- Can be made up to 1500X1500 mm