Ceramic formulation: Particle size

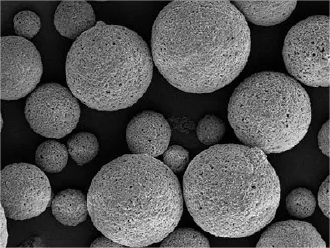

The formula of ceramic refers to that under the configuration of raw materials of different shapes and different particle sizes, the physical and chemical properties of the finished products under the corresponding ceramic production process conditions and firing conditions meet the requirements. Many people think that the formula is just a proportion of raw materials, this view is really wrong, through a variety of analysis and characterization of foreign products, and then reverse calculate the selection of raw materials, however, different auxiliary materials or organic compounds have a great impact on the production process of ceramics. That's why we draw cats like tigers. If the formula of ceramic products can be calculated, then those mysterious antiques in our country will lose their color. Ceramics are products formed by sintering powders, and the size and distribution of the particles in these powders are directly related to the final physical and chemical properties of the product. Therefore, the control of particle size is a key part of the development and production of ceramics, as it enables producers to ensure that their products meet the requirements of users.

Effect of particle size on ceramics:

(1) The particle level has a great influence on the compactness of the ceramic green. When the particle size difference is large, the demand for auxiliary materials increases.

(2) Through the adjustment of particle grading design, the physical and chemical properties of ceramics such as strength and porosity will change.

(3) Under reasonable collocation, materials with more coarse particles have higher thermal shock resistance.

Molding size

1) The molding particle size refers to the combined state of the raw materials under the basic formula after being stressed (molding process conditions).

- Volume: the volume achieved after accumulation of different particle sizes.

- Area: the area achieved after different particle size accumulation.

2) Influencing factor

- The settlement during the mixing process: different particle size powder in the mixing, affected by gravity and other factors will produce settlement.

- The combination under the molding process: under the influence of different molding processes, raw materials and auxiliary materials to achieve a suitable state.

The combination state of particle size after sintering

Under different sintering temperatures and conditions, different particle combinations will occur corresponding to the sintering conditions.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!