High purity graphite - a key consumable in the third generation semiconductor field

With the gradual mass production of conductive SiC substrates, higher requirements are put forward for the stability and repeatability of the process. In the later period, we must face the challenge of "growing fast, growing thick, and growing up", in addition to the improvement of theory and engineering, we also need more advanced thermal field materials as support. High purity graphite has high temperature resistance, good electrical conductivity and chemical stability, and has become a key material in the semiconductor field.

High purity graphite support the field

At present, the mainstream commercial silicon carbide single crystal growth is using PVT method. This method uses induction coil to heat, and the high-density graphite heating element will be heated under the action of eddy current. The silicon carbide (SiC) powder is filled with the bottom of the graphite crucible, the silicon carbide (SiC) seed crystal is bonded inside the graphite crucible cover which has a certain distance from the raw material surface, and then the graphite crucible as a whole is placed in the graphite heating body, and the raw material of silicon carbide (SiC) is placed in the high temperature zone by adjusting the temperature of the external graphite felt. The silicon carbide (SiC) seed crystal is correspondingly in the low temperature region.

In this process, the area composed of the crucible and the surrounding insulation material is the most important area for the growth of SiC single crystals, which is called the hot field area. At present, the international SiC single crystal growth furnace adopts intermediate frequency heating technology, which is characterized by the crystal growth chamber can reach a very high temperature (up to 3000 ° C), in this high temperature scenario, graphite and related products can withstand such high temperatures, and it does not react with SiC sublimate at such high temperatures. Therefore, the crucible and insulation materials used for growing SiC require the use of high-purity graphite and carbon-based materials. High purity is a key requirement of semiconductor graphite, especially in the process of crystal growth, impurities in graphite is a key determinant of crystal quality, impurity content should be kept below 5 parts per million.

Defects of porous graphite

SiC crystal growth is difficult, long research and development cycle, high research and development costs, how to reduce research and development costs, accelerate research and development progress, improve crystal quality has become a problem for the development of the industry. In recent years, the introduction of porous graphite (PG) has effectively improved the quality of crystal growth, and the addition of porous graphite plates in SiC crystal growth furnace is one of the hot spots of industry research.

(a)Traditional long crystal furnace,(b)Long crystal furnace of porous graphite plate

Dongui University of South Korea mentioned in the essay that by inserting a porous graphite plate above the SiC powder, good crystal area mass transfer is achieved, which can improve a variety of technical problems existing in the traditional long crystal furnace. The study found that the application of PG helped reduce the number of microtubules and other defects.In addition, porous graphite is also one of the core technologies to solve the length and thickness of SiC crystals, because it can balance the gas phase components, Isolation of trace impurities, adjust the local temperature, reduce carbon packaging and other physical particles, under the premise of meeting the crystal availability, the crystal thickness can be significantly increased.

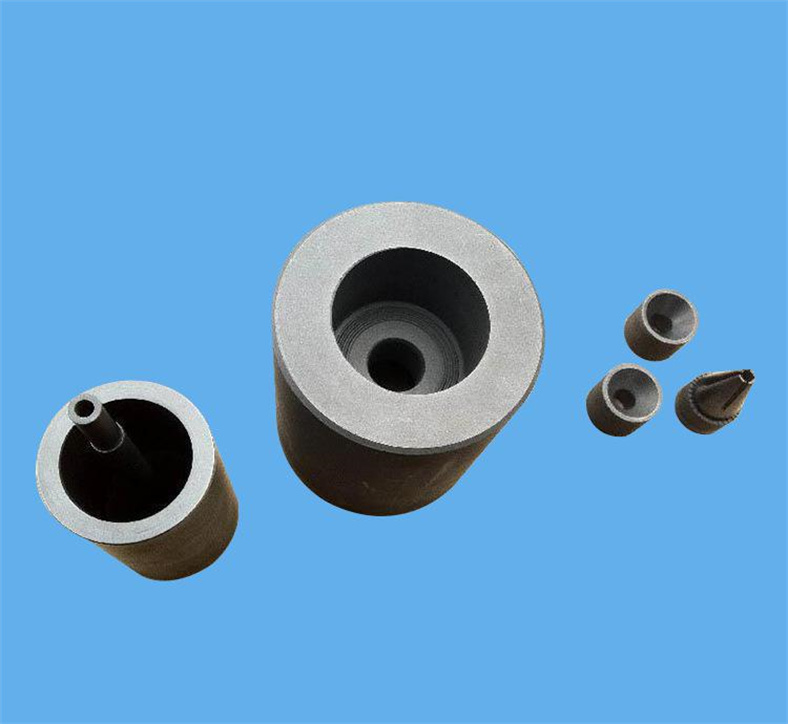

Graphite base

Graphite bases are a component commonly used to support and heat single crystal substrates in metal-organic chemical vapor deposition (MOCVD) equipment. The thermal stability, thermal uniformity of performance parameters of SiC coated graphite base play a decisive role in the quality of epitaxial material growth, so it is the core key component of MOCVD equipment. In the epitaxial process of silicon carbide, the wafer is carried on a graphite disk, which has a bucket type, a pancake type and a single wafer graphite disk. The graphite disk is generally coated with SiC, which is tightly bonded to the graphite parts, extending the service life of the graphite parts and achieving the high purity surface structure required for the production of semiconductor materials. There is also TaC coating, TaC coated graphite compared to SiC coated graphite products, has better heat resistance.

Graphite parts for ion implantation

Ion implantation is a technology to accelerate the ion beam such as boron, phosphorus and arsenic to a certain energy, and then injecting it into the surface of the wafer material to change the properties of the surface material. The materials that make up the components of the ion implantation device are required to have high purity materials with excellent heat resistance, thermal conductivity, less corrosion caused by the ion beam and low impurity content. The high purity graphite meets the application requirements and can be used in the flight tubes of ion implantation equipment, various slits, electrodes, electrode covers, catheters, beam terminators.....etc. At present, the cost of silicon carbide substrate is about 47% of the overall device cost, of which the cost ratio of thermal field materials such as coated graphite is the highest.

As far as SiC coated graphite base is concerned, the international mainstream suppliers of SiC coated graphite base are Dutch Xycard, Germany SGL, Japan Toyang Carbon, the United States MEMC corporation, which basically occupy the international market. In Singapore, it is necessary to gradually open the situation of localization of SiC coated graphite base, and the SiC coated graphite base industry needs to accelerate the process.

Fountyl Technologies PTE Ltd offers high precision SIC chuck, pin chuck, grooved chuck, porous ceramic chuck.