Infrared Optical Design Talk! Material or big problem!

Infrared optical system in the design process may feel that the difficulty is relatively low, a conventional objective lens may be three mirrors to get it done, this is a relatively entry-level design, complex and infrared zoom, multi-channel composite system. There are many special features in infrared design compared to visible light system design. In particular, the stray light design analysis needs to take into account 100% cold diaphragm efficiency, as well as daffodil effect and so on.

In order to achieve 100% cold diaphragm efficiency, there is a match between the real exit pupil and the cold window of the detector at the time of design, and a match between the aperture and the F number to ensure that the radiation reaching the detector is the target object, and does not include the lens intrinsic radiation.

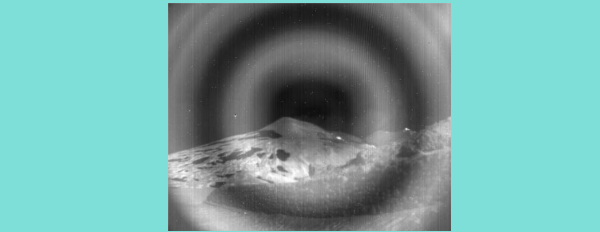

The daffodil effect is a fancy name for cold reflection. Daffodils are actually a Greek fairy tale about a goddess admiring herself in water. The image sent back by the detector through the optical system is described here. The detector radiates as an infrared object and reflects back through a certain surface of the optical system in front of it to reach the detector for imaging. This actually happens a lot with our visible-light lenses. The following is the analysis of stray light from a mobile phone lens, it can be seen that a point on the detector will be reflected by the protective glass in front of the detector. The size of the two spots is not the same, the image is smaller than the nearest Airy spot, and the reflected spot is large, and the detector is characterized by defocus, Newton's ring.

Infrared is only similar to this, the reason is that the infrared material refractive index is relatively high, the anti-reflection film efficiency is difficult to do high, more reflected energy, if the design of the detector's infrared radiation, through the optical system reverse propagation to a certain surface, the light and the surface normal Angle is very small, it will return the original way, daffodil effect. So there is a great risk of filters or Windows in parallel optical paths in infrared optical systems.

Germanium is a commonly used infrared material with a refractive index slightly greater than 4.0. In MWIR band, the refractive index of germanium changes rapidly, resulting in large dispersion. The refractive index inhomogeneity of monocrystalline germanium ranges from 0.00005 to 0.0001, while that of polycrystalline germanium ranges from 0.0001 to 0.00015.

In addition to the analysis and relaxation of the refractive index tolerance of the material during optical design, it is also necessary to actually measure the refractive index of the material for some complex materials, which is also one of the tasks that need to be carried out, of course, this work is implemented by the processing party or the material provider.

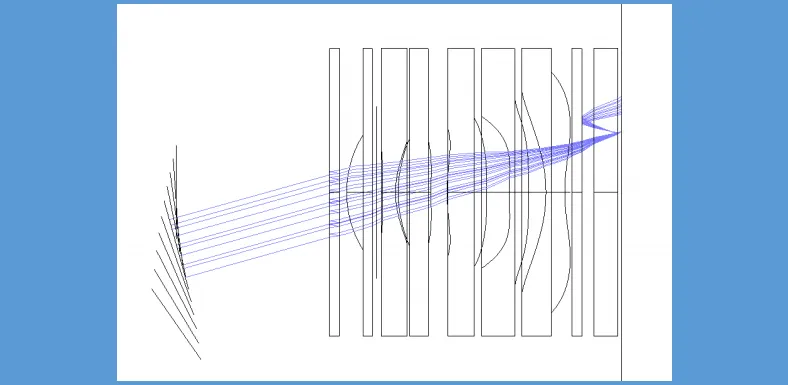

Use the infrared parallel light of known wavelength to incident on a wedge of infrared material, the light deflects, emerges from the AC plane, measures the incident Angle and exit Angle, wedge Angle, and then you can calculate the refractive index of the current wavelength, and then change the wavelength, test the deflection Angle under different wavelengths, and calculate the refractive index of the infrared material under different wavelengths. The wavelength of the infrared light source is screened by the monochromator, and then collimated by the paraboloid, into the wedge Angle sample to be measured, and then the Angle is measured by the infrared Angle measuring instrument, and the refractive index is calculated.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!