Introduction of aluminum nitride ceramic heater, a key component of semiconductor equipment

Today we introduce to you the key components of semiconductor equipment - Ceramic Heater and related manufacturers. In the manufacturing process of semiconductor devices such as integrated circuits, various treatments such as film forming and etching are performed on semiconductor wafers. In the wafer manufacturing process, the wafer needs to be heated to a certain temperature, and the wafer temperature uniformity has a very strict requirement, because the wafer temperature uniformity has a very important impact on the quality of semiconductor chips; At the same time, it is also necessary to work in vacuum, plasma, chemical gas environments, which requires the use of ceramic heaters.

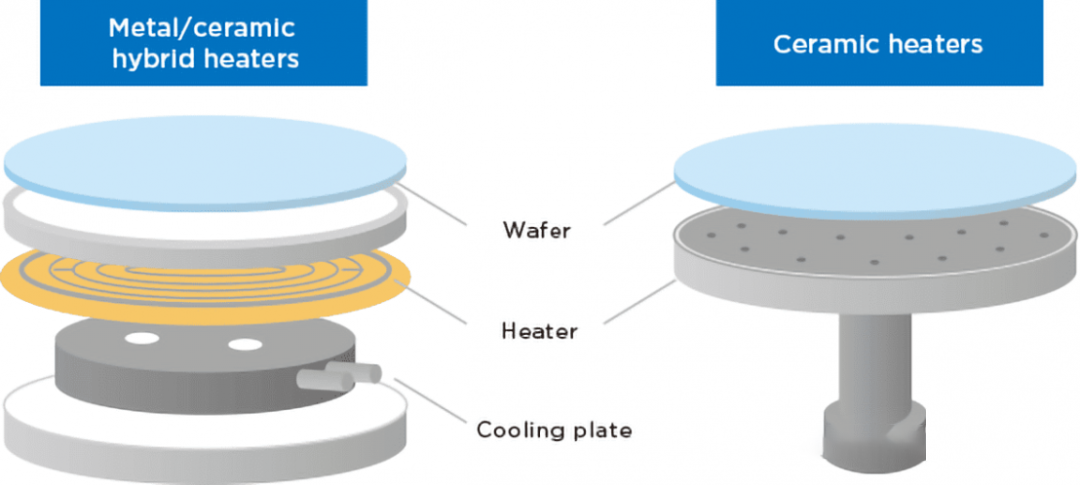

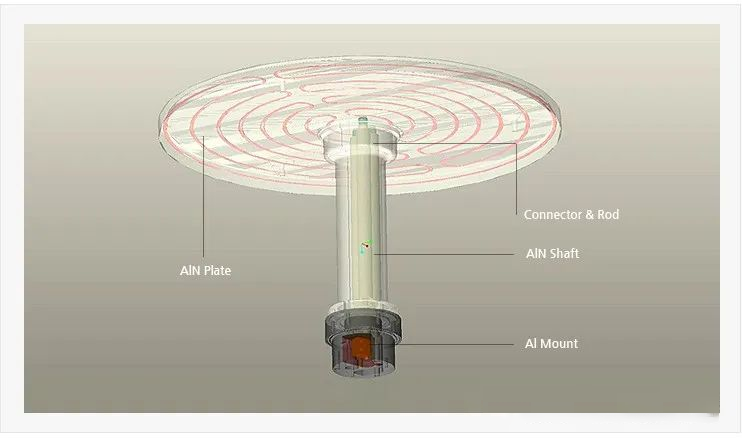

Ceramic heaters are important components in devices for semiconductor film deposition, which can achieve uniform temperature distribution, uniform heating of wafers, and enable high-precision reaction on the substrate surface and the formation of films. Generally, the ceramic heater comprises a ceramic substrate with a wafer loading surface and a cylindrical support body on the back to provide support for it. In addition to a resistance heating element circuit for heating, the conductive body such as RF electrode and electrostatic chuck electrode is also setted on the internal or surface of the ceramic substrate.

Ceramic heaters usually use aluminum nitride ceramics, aluminum nitride has electrical insulation and excellent thermal conductivity, It is ideal for applications that require heat dissipation; In addition, because its coefficient of thermal expansion is close to silicon and has excellent plasma resistance, it can be used to manufacture semiconductor processing equipment components.

According to the Research report of Business Research Insights, the global aluminum nitride ceramic heater market scale is $33 million in 2022, and it is expected to reach $78.529 million by 2031, with a compound annual growth rate of 10% during the forecast period. The global ceramic heater market is dominated by foreign companies, and at present, the situation for self-regulated level of Singapore ceramic heaters is consistent with other semiconductor parts and key raw materials such as electrostatic chuck, and Singapore and domestic enterprises are very few to achieve.

Fountyl Technologies PTE Ltd, founded in 2023, has gradually broken the foreign monopoly after years of research and development, and its products such as ceramic chuck, pin chucks, ceramic arms, ceramic square beams, ceramic guides, bearing bushings, and heating tables are widely used in the world's first-line semiconductor equipment manufacturers and electronic manufacturing enterprises.

Relying on the leading material capabilities and rich processing and manufacturing technology, its advanced ceramic material parts cover a broad range of downstream fields. Advanced ceramics are mainly used in wafer manufacturing process equipment, and have now entered the etching, film deposition, ion implantation, lithography and oxidation diffusion equipment, and are used in batch semiconductor process equipment and production processes. Advanced ceramics for semiconductor equipment include toroidal cylinders, load-bearing, grippers and modules in ceramic heaters.