Introduction to microporous ceramics technology

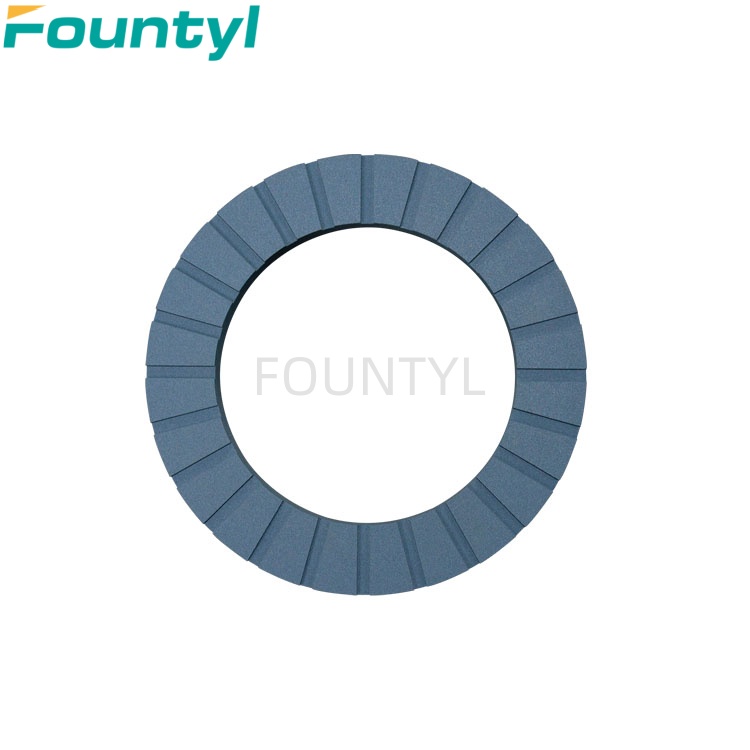

Fountyl Technologies PTE Ltd can manufacture high-end porous ceramic vacuum chuck, porous ceramics, Ceramic chuck, adsorbent fabrics and silicon wafers, wafers, ceramic wafers, flexible screens, glass screens, circuit boards and various non-metallic materials.

Porous ceramics Overview

When it comes to microporous ceramics, we have to mention porous ceramics first.

Porous ceramics is a new type of ceramic material, also known as pore functional ceramics, after high temperature calcination and refining, because in the firing process will produce a very porous structure, so it is also known as porous ceramics, is a large number of ceramic materials with mutual communicated or closed pores in the body.

Classification of porous ceramics

Porous ceramics can be classified from dimensionality, phase composition and pore structure (pore size, morphology and connectivity).

According the pore size, it is divided into: coarse porosity porous ceramics (pore size >500μm), large porosity porous ceramics (pore size 100~500μm), medium porosity porous ceramics (pore size 10~100μm), small porosity porous ceramics (pore size 1~50μm), fine porosity porous ceramics (pore size 0.1~1μm) and micro-porosity porous ceramics. according to the pore structure, porous ceramics can be divided into uniform porous ceramics and non-uniform porous ceramics.

Definition of microporous ceramics

Microporous ceramics is a uniform pore structure micro-porosity porous ceramics, is a new type of ceramic material, is also a functional structural ceramics, as the name suggests, is in the ceramic interior or surface containing a large number of opening or closing micro-pores of the ceramic body, the micropores of microporous ceramics are very small, its aperture is generally micron or sub-micron level, is basically invisible to the naked eye. However, microporous ceramics are actually visible in daily life, such as the ceramic filter applied in the water purifier and the atomization core in the electronic cigarette.

History of microporous ceramics

In fact, the global research on microporous ceramics began in the 1940s, and after successfully promoting its application in the dairy industry and beverage (wine, beer, cider) industry in France in the early 1980s, it began to be applied to sewage treatment and other corresponding fields.

In 2004, the world porous ceramics market sales volume is more than 10 billion US dollars, due to the successful application of microporous ceramics in precision filtration separation, its market sales volume at an annual growth rate of 35%.

Manufacture of microporous ceramics

The principles and methods of porous ceramics include particle stacking, pore addition agent, low temperature underfiring and mechanical processing. According to the method of pore formation and pore structure, porous ceramics can be divided into granular ceramic sintered body (microporous ceramics), foam ceramics and honeycomb ceramics.

Microporous ceramics is a new type of inorganic non-metallic filter material, microporous ceramics is composed by aggregate particles, binder, pore of 3 parts, quartz sand, corundum, alumina (Al2O3), silicon carbide (SiC), mullite (2Al2O3-3SiO2) and ceramic particles as aggregate, mixed with a certain amount of binder, and after high temperature firing with pore-forming agent, Aggregate particles, binders, pore-forming agents and their bonding conditions determine the main characteristics of ceramic pore size, porosity, permeability. Aggregates, like adhesives, are selected according to the purpose of product use. It is usually required that the aggregate has high strength, heat resistance, corrosion resistance, close to the ball shape (easy to construct into filter conditions), easy granulation within the given size range, and good affinity with the binder. If the aggregate substrate and particle size are the same, other conditions are the same, the product's pore size, porosity, air permeability indicators can achieve the ideal purpose.