Semiconductor equipment industry in-depth review

Semiconductor equipment is the cornerstone to support the development of the electronics industry, but also the semiconductor industry chain upstream market space is the broadest, the most important strategic value of a link. In terms of the domestic market, the rationalization of the supply chain structure and the needs of geopolitics have brought about the momentum of domestic substitution in the domestic equipment market. Therefore, domestic equipment manufacturers enjoy the double growth rate of fab expansion + localization.

Semiconductor equipment classification, development status and driving factors

1 Classify

According to the application link of the industrial chain, semiconductor equipment can be divided into two categories: front process equipment (wafer manufacturing) and back process equipment (packaging and testing). The post-process equipment can also be subdivided into packaging equipment and test equipment. The front channel equipment in the equipment occupies 80%-85% of the entire market, of which the lithography machine, etching machine and film equipment are the three largest links in terms of value, and their respective market size has reached more than 20% of the total number of front channel equipment. As a result, many of the world's top ten semiconductor equipment manufacturers are platform companies that span multiple semiconductor process links.

2. Development status

The large and complex nature of the semiconductor industry chain makes it difficult for one company to cover all equipment areas. Companies from all countries around the world share the entire market. From the perspective of the global competition pattern in 2021, the revenue scale of the first echelon top5 is about 10 billion or more, and the revenue volume of the top10 companies should also be more than 2 billion US dollars. Compared with the revenue of domestic equipment leader NAura's electronic equipment business (including integrated circuit business and pan-semiconductor business) of about 7.95 billion yuan in 2021, there is still a large gap between the revenue scale of China's semiconductor equipment industry and the industry's leading manufacturers, and there is huge space for replacement.

3. Driving factors

Advanced process development, process improvement, semiconductor equipment ushered in new needs.

(1) New energy, AIot promotes the development of mature process equipment to accelerate the volatile growth of the semiconductor equipment industry, and new changes have occurred in the downstream electronic application terminals of the industrial chain, generating new demand. The semiconductor equipment industry shows a trend of rising volatility.

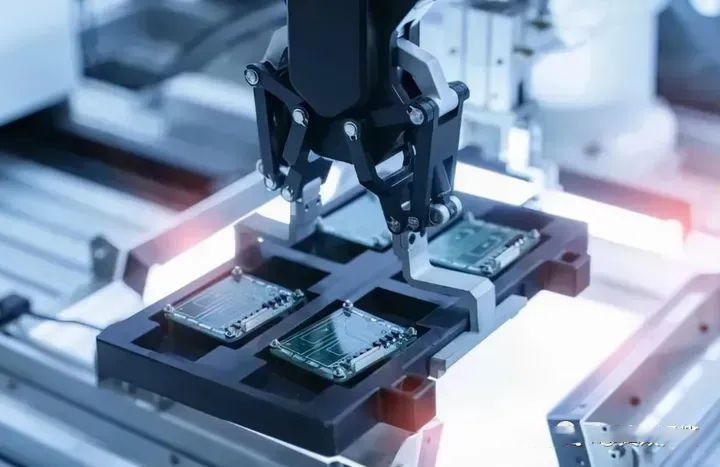

(2) From substrate to chip: the process determines the change in equipment use demand, the refinement of the chip production line, a high degree of automation, and the chip/equipment have high requirements for the environment.

Semiconductor equipment industry chain review and related companies

Semiconductor equipment is mainly composed of seven equipment components: lithography equipment, etching equipment, cleaning equipment, film deposition equipment, ion implantation equipment, mechanical polishing equipment and packaging, testing equipment. Let's analyze them separately.

1. Lithography machine: the continuation of Moore's Law

2. Etching machine: microcosmic engraver

3. Film deposition equipment: founder of integrated circuit

4. Other front-track equipment: the proportion is not high but one is indispensable

In addition to the three core processes of lithography, thin film deposition and etching, other front-end equipment, although not high in proportion, is equally indispensable. From the perspective of chip manufacturing process, including coating development equipment, cleaning equipment, ion implantation equipment and diffusion equipment. The coating developing equipment and the lithography machine jointly complete the lithography process. The cleaning machine and CMP work together to complete the cleaning and polishing of each step of the chip. Ion implanters and diffusion furnaces focus on the doping process.

5. Test equipment: wafer quality gatekeeper

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!