Semiconductor technology and equipment: chip testing and equipment

Testing is an important means to ensure function and yield. Chip testing can be divided into two main parts. CP(chip probering) and FT(final test). Some chips also perform SLT (system leve test). There are also specific requirements for chips that require some reliability testing.

CP test

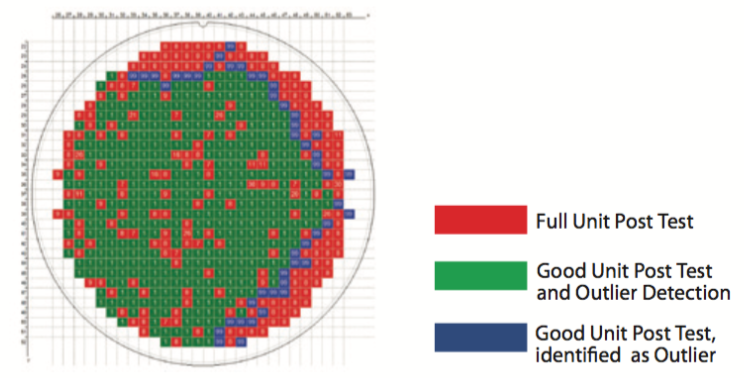

CP (Chip Probing) test is also called wafer test, which is to test wafer before the chip is not packaged, so that the problematic chip can be removed before packaging, saving the cost of packaging and FT. CP testing sits between wafer fabrication and packaging throughout the chip-making process. After the Wafer is made, thousands of naked dies (unpackaged chips) are regularly filled with the entire Wafer. Since the chip has not been sliced, the pins of the chip are all exposed, and these extremely small pins need to be connected to the Tester through a thinner Prober.

CP test mainly measures the following aspects:

1.SCAN: to check whether the logical functions of the chip are correct or not.

2.Boundary SCAN: to check whether the pin function of chip is correct or not.

3. Memory: Chips are often integrated with various types of memory (such as ROM/RAM/Flash). In order to test the memory read and write and storage functions, BIST (Built-In SelfTest) logic is usually added in advance during the design for memory self-test. The chip enters various BIST functions through special pin configuration, and the BIST module feedbacks the test results to the Tester after the completion of self-testing.

4.DC/AC Test: The DC test includes the Open/Short test for the chip Signal PIN, the PowerShort test for the power PIN, and the test to see if the chip DC current and voltage parameters meet the design specifications or not.

5.RF Test: For wireless communication chips, the function and performance of RF is crucial. RF tests are performed in CP to check whether the RF module logic function is correct. Further performance tests are also performed on the RF at FT.

6. Other Function tests: it is used to test whether other important functions and performance of the chip meet the design specifications or not.

7. The closer a wafer is to the edge, the greater the chance of a die (a small check, which is an unpackaged chip) going wrong.

FT(final test)

FT(final test) is the final test, which is carried out after the chip is packaged. FT testing is a chip level test that establishes an electrical connection between the automated test device (ATE) and the packaged chip through a Loadboard and a test Socket. The purpose of FT testing is to select products that meet the design specifications to sell to customers.

The FT- test project is also determined according to the functions and characteristics of the chip. Common FT test items are:

1, Open/short test: to check whether there is an open or short circuit in the chip pin.

2, DC test: to check the DC current and voltage parameters of the device.

3. Eflash test: to check the embedded flash function and performance, including various parameter of reading and writing, action, power consumption and speed.

4, Function test: to test the logical function of the chip.

5, AC test: to verify the specifications of the AC, including the quality of the AC output signal and the actual parameters of the signal.

6, RF test: This is for the chip with an RF module, mainly to verify the function and performance parameters of the RF module.

7. DFT test: Design for Test, mainly includes scan design and self-test of internal parts, that is BIST(Build In Self Test).

SLT

SLT is the abbreviation of System Level Test. SLT is used when other test coverage rate cannot be met. The other is to control the cost, because the test cost of ATE is relatively high. The SLT test puts the chip on a test board, which can be used to verify the various functions of the chip. Because they control multiple test machines, batch testing can be achieved.

The hardware equipment required for SLT test includes test board, test socket, Handler, Change Kit, test host and cable. SLT test is a customized test, the software part has high flexibility, does not need to develop based on automated test platform, completely developed by test engineers. SLT test usually includes chip function test, high-speed interface test and DDR memory related test. same as the FT test, the program will physically bin the chip according to the test result Pass or Fail.

In addition to the above three main tests, some chips may also undergo some reliability tests, including the following:

1, ESD:electrostatic immunity test

2, Lateh up:latch test

3, HTOL:high temperature working life test

4, LTOL:low temperature working life test

5. TCT:temperature cycle test

6. HAST: high accelerated temperature and humidity stress test

7, Other tests for special requirements

Test equipment

Chip testing is complex, and it is a mass production thing, so large-scale automated testing is the only solution, and manual or bench test is not able to complete such a task. In semiconductor testing, test machines, sorters and probe stations are the three key devices that work together to ensure the accuracy and efficiency of the test.

1,Test machine

Testing machine is one of the core equipment of semiconductor testing. It provides functions such as power supply, instrument and signal processing to test the electrical characteristics and verify the functions of the chip. The test machine usually has multiple slots for inserting the chip to be tested. According to different test requirements, the test machine can carry out various tests of voltage, current, power, frequency, timing. It can automately execute the test procedures and generate test reports and data analysis results.

The key technologies of the tester include test program development, test point wiring, signal acquisition and processing. In order to improve the test efficiency and accuracy, the test machine is usually equipped with high-speed digital signal processor, analog converter, clock management of advanced technologies. In addition, the test machine also needs to have good flexibility and scalability to adapt to changes in different chip types and test requirements.

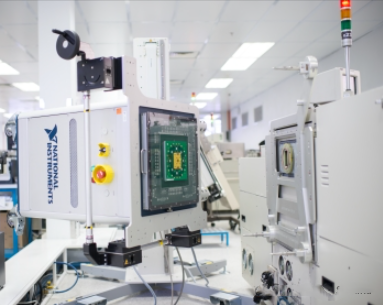

At present, the largest ATE (Automatic Test Equipment) companies are Teradyne and Advantest, NI is currently doing this, and many small companies are using NI's instruments. Domestic companies are well-known Changchuan technology, Jin Haitong and so on.

2, Sorting machine

The sorting machine is another important device in semiconductor testing. It is mainly used to classify and sort the chip under test according to certain standards or requirements. The sorting machine usually has high-speed image processing and recognition technology, which can carry out optical detection and resolution of the chip, and judge its quality and conformity.

The key technology of the sorting machine includes image sensor, image processing algorithm, motion control system. Through optical inspection and image processing, the sorting machine can quickly and accurately identify and classify chips, pick out unqualified products, and ensure that only high-quality chips flow into the next stage of production. The high efficiency and accuracy of sorting machine are of great significance to improve the production efficiency and reduce the rate of defective products.

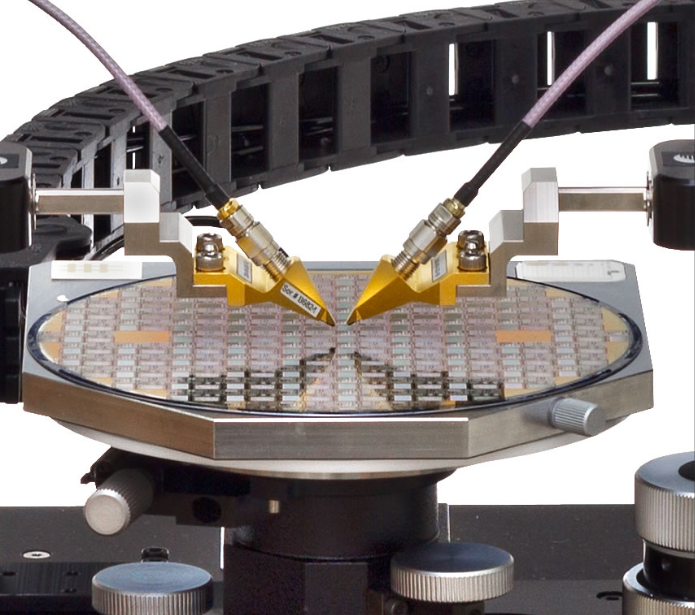

3, Probe station

The probe station is one of the key equipment used in chip testing. It provides a platform for fixing and supporting the test probe, ensuring that the probe can reach the test point on the chip stably. The main function of the probe station is to provide stable mechanical structure, reliable probe fixing and fine tuning, good electrical conductivity and insulation characteristics.

The key technologies of the probe station include mechanical structure design, probe fixing and fine tuning mechanism, conductive material selection and treatment. By precisely controlling the position and pressure of the probe, the probe station can ensure good contact between the probe and the chip and provides a stable test environment. The high precision and stability of the probe station play a crucial role in the accuracy and reliability of the test results.

Fountyl Technologies PTE Ltd, is focusing on semiconductor manufacturing industry, main products include: Pin chuck, porous ceramic chuck, ceramic end effector, ceramic square beam, ceramic spindle, welcome to contact and negotiation!