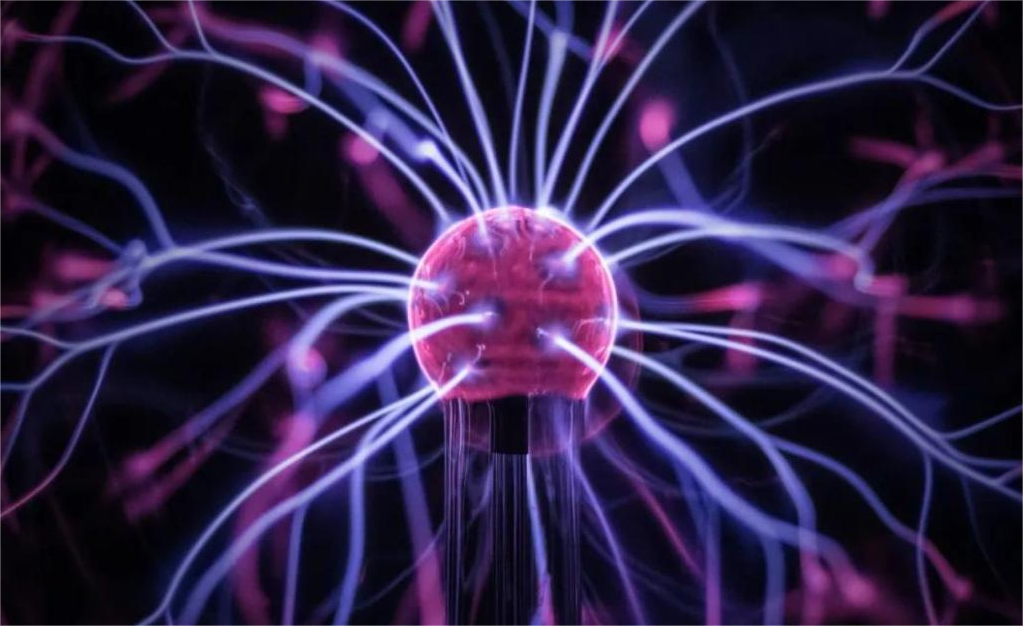

An essential element in chip manufacturing- Plasma

Plasma was first discovered by William Crookes in 1879 and named "plasma" by Irving Langmuir in 1929. The application of plasma in chip manufacturing is very common and important, it can be said that without plasma, chip production would not be possible. Plasma is almost always involved in dry etching, PVD, CVD, wafer surface modification and lithography.

A necessary element in chip manufacturing - vacuum

Vacuum is very important in semiconductor manufacturing, in the semiconductor industry, the vacuum environment is used in various processes, It includes Physical Vapor Deposition (PVD), Chemical Vapor Deposition (CVD), and Atomic Layer Deposition (Atomic Layer Deposition). ALD, Ion Implantation, Plasma Etching, and so on.

The world's Top10 semiconductor companies, and its main technical strength

Here are the top 10 semiconductor companies in the world by market capitalization and sales revenue.

Why can't the furnace tube silicon carbide boat be cleaned dry?

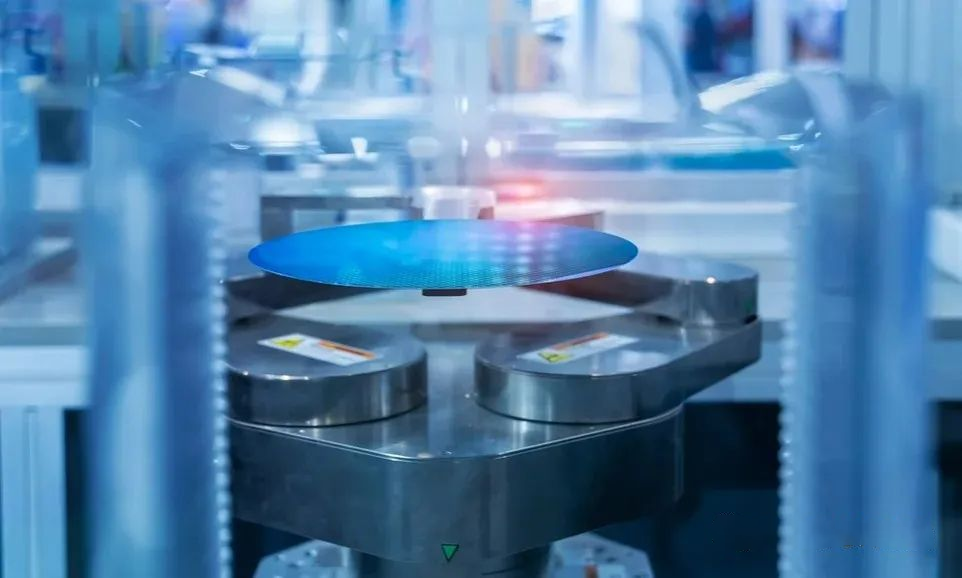

SiC boat, is silicon carbide boat. Silicon carbide boat is used in the furnace tube, loaded with wafers for high temperature treatment of high temperature accessories. Because silicon carbide material has high temperature resistance, chemical corrosion resistance and good thermal stability, it is widely used in various heat treatment processes, such as diffusion, oxidation, CVD, annealing and so on.

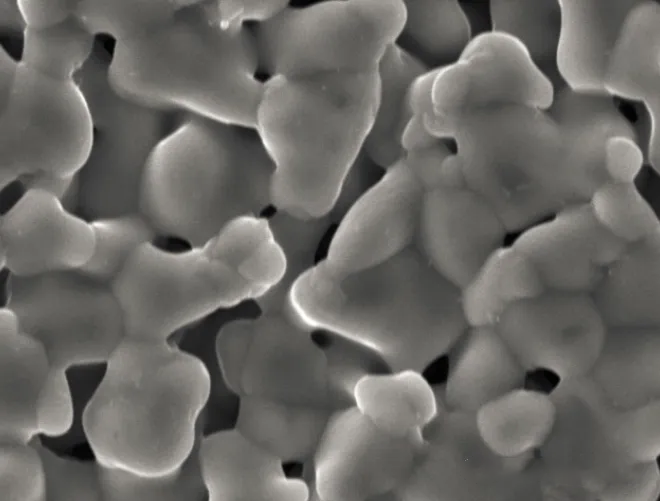

Gel injection molding of silicon carbide ceramics

Gel system is the core component of gel injection molding technology, and its selection directly affects the performance of the final product. Commonly used gel systems include organic gel, inorganic gel and composite gel. When selecting a gel system, it is necessary to consider its stability, viscosity, curing speed, and adaptability to the specific material.

Special ceramics: Press molding - binder

Organic binders are often used in dry pressing and isostatic pressing.

Ceramic parts & Quartz Parts & perfluorinated Seals & Electrostatic chuck....

At present, domestic vacuum semiconductor parts are equivalent to the development stage of domestic semiconductor equipment about 3 to 5 years ago, and several domestic suppliers of various parts and components continue to research and development, but are limited by the technology gap has not fully met the needs of downstream semiconductor equipment manufacturers

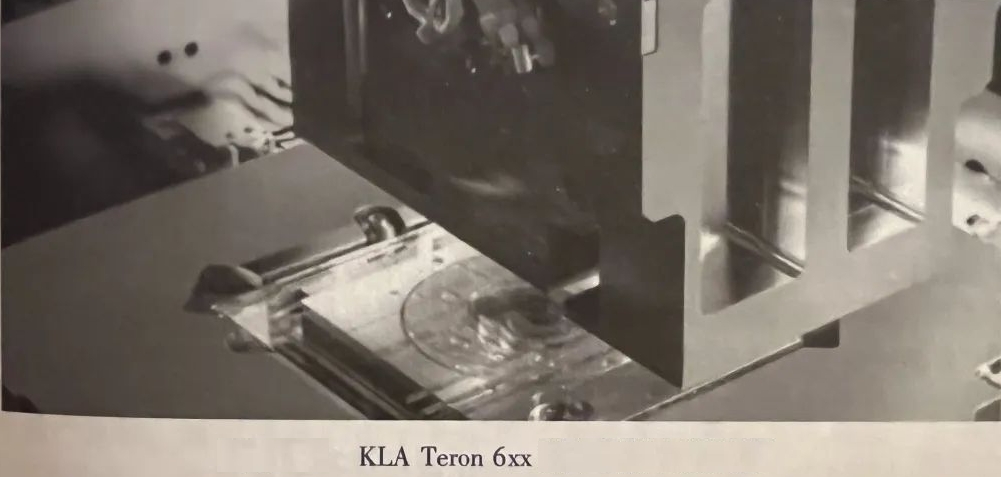

Domestic and foreign testing equipment leading enterprises and equipment introduction

Domestic and foreign testing equipment leading enterprises and equipment introduction

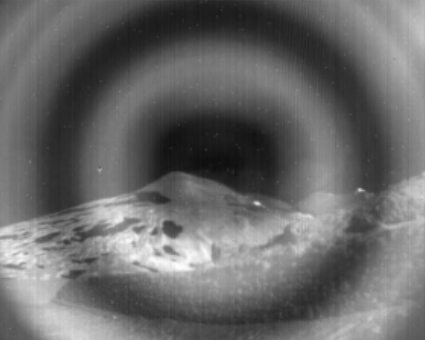

Infrared Optical Design Talk! Material or big problem!

Infrared optical system in the design process may feel that the difficulty is relatively low, a conventional objective lens may be three mirrors to get it done, this is a relatively entry-level design, complex and infrared zoom, multi-channel composite system.

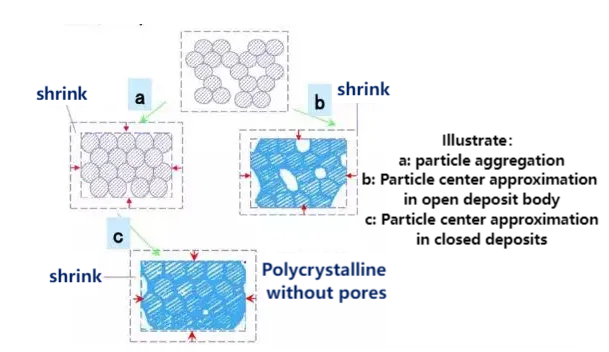

Sintering of ceramics -- mechanism and method of sintering

Sintering is an important process in powder metallurgy, ceramics and refractory materials