Iteknoloji yeMveliso

Inkqubo yokuvelisa engqongqo kunye nemveliso echanekileyo ephezulu kunye nezixhobo zokuvavanya ukuqinisekisa umgangatho ophezulu weemveliso.

Inkqubo yokuCofa okomileyo

Ukucinezela okomileyo yenye yezona nkqubo zisetyenziswa kakhulu ekubumbeni, iingenelo eziphambili kubuchule obuphezulu bokubumba, ukutenxa ubungakanani obuncinci beemveliso ezibunjiweyo, zilungele ngakumbi ubungakanani becandelo elincinci lemveliso ye-ceramic, njengesiseko sevalve ye-ceramic, ipleyiti ye-ceramic, i-ceramic plate. ring...njl.

Inkqubo ye-Isostatic Pressing kunye neempawu

I-Isostatic Pressing Molding inezi zinto ziluncedo zilandelayo ngaphaya kokuBunjwa kwentsimbi yokufa:

I-Ceramic Sintering

I-Ceramic blank iqulunqwe ngamasuntswana amaninzi aqinileyo phambi kokuba i-sintering, kukho inani elikhulu leepores emzimbeni, i-porosity ngokubanzi yi-35% ~ 60% (oko kukuthi, ukuxinana okungenanto yi-40% ~ 65%), ixabiso elithile lixhomekeke kwiimpawu zomgubo ngokwawo kunye nendlela yokubumba kunye nobuchwepheshe obusetyenzisiweyo. Xa indawo engenanto eqinileyo ifudunyezwa kubushushu obuphezulu, amasuntswana ekudluliselweni okungenanto, emva kokufikelela kwiqondo lobushushu elithile, into engenanto iyancipha, ukukhula okuziinkozo kwenzeka, kukhatshwa kukupheliswa kweepores, kwaye ekugqibeleni into engenanto iba yinto eshinyeneyo ye-polycrystal ceramic. iqondo lobushushu elingaphantsi kwendawo yokunyibilika, le nkqubo ibizwa ngokuba sintering.

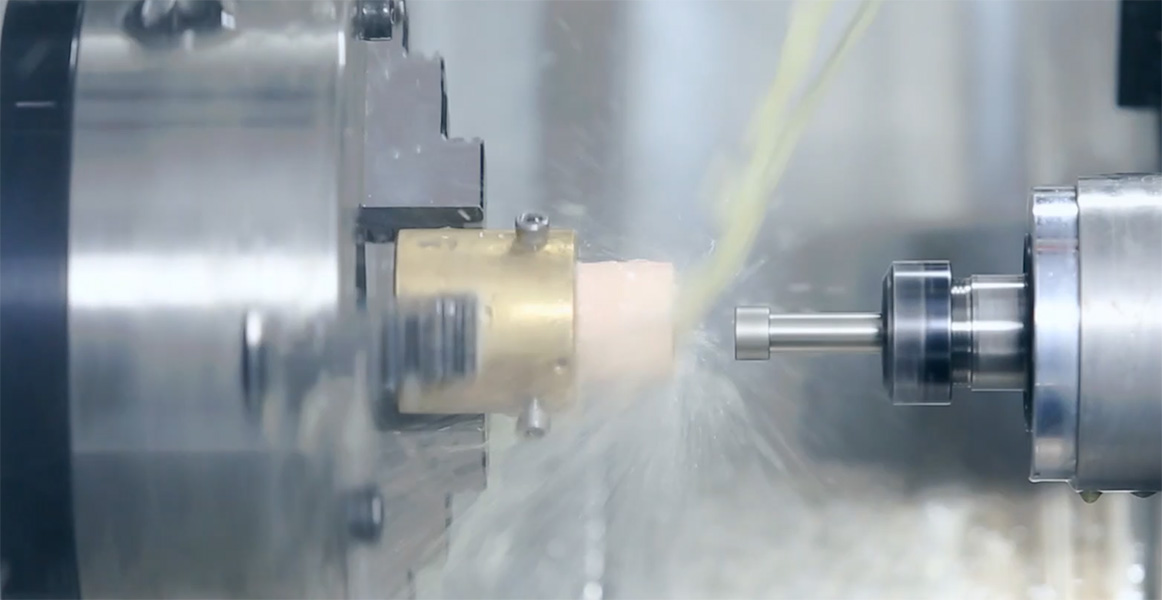

UkuSila Ngaphakathi Nangaphandle kweSetyhula

Ukusila ngaphakathi nangaphandle kwisetyhula (ekwabizwa ngokuba kukusila okuphakathi) kusetyenziselwa ukugaya umphezulu wesetyhula wangaphandle kunye negxalaba lomsebenzi. I-workpiece ifakwe embindini kwaye ijikeleziswa sisixhobo esibizwa ngokuba ngumqhubi weziko. Amavili okugaya kunye nezixhobo zokusebenza zijikelezwa ngesantya esahlukileyo ngeenjini ezahlukeneyo. Isikhundla sokubambelela kwimveliso sinokuhlengahlengiswa kwi-Angle ukuvelisa i-taper. Zintlanu iintlobo zokugaya ngaphandle kwedayimitha yangaphandle (OD), idiameter yangaphakathi (ID) yokugaya, i-punch grinding, i-creep feed grinding kunye nokusila okungenaziko.

UkuSila kweDiameter yangaphandle

Ukusila kwedayamitha yangaphandle kukusila kumphezulu ongaphandle wento phakathi kweziko kunye neziko. Umbindi yiseli yesiphelo enenqaku elivumela into ukuba ijikeleze. Xa ivili lokugaya lidibana nento, ivili lokugaya libuye lijikeleze kwicala elifanayo. Oku kuthetha ngokufanelekileyo ukuba xa uqhagamshelwe, iindawo ezimbini ziya kuhamba ngendlela echaseneyo, eyenza umsebenzi uzinzile kwaye uthintele ngaphantsi.

UkuSila kweDiameter yangaphakathi

Ukusila kwidayamitha yangaphakathi kukusila ngaphakathi kwento. Ububanzi bevili lokugaya buhlala bungaphantsi kobubanzi bento. Into ibanjwe yi-fixture, ephinda ijikeleze into kwindawo. Kanye njengokusila kwedayamitha yangaphandle, ivili kunye nento zijikeleza kumacala achaseneyo ukuze icala loqhagamshelwano lemiphezulu emibini apho kusila lichasane.

UkuSila ngeFlethi

Ukusila okucaba ngowona msebenzi uqhelekileyo wokusila. Itheknoloji yokucubungula esebenzisa ivili elijikelezayo lokugaya ukugaya ubuso besinyithi okanye izinto ezingezizo zetsimbi ukususa i-oxide layer kunye nokungcola phezu kwendawo yokusebenza, ukwenzela ukuba ubuso bayo buhlanjululwe ngakumbi. I-grinder flat sisixhobo somatshini esenzelwe ukubonelela ngeendawo ezichanekileyo zokusila, nokuba ubungakanani obubalulekileyo okanye ukugqitywa kwendawo. Ukuchaneka okuthe ngqo kwe-grinder flat kuxhomekeke kuhlobo lwayo kunye nokusetyenziswa, ububanzi buyi-300mm yediski, ukuchaneka kweplanimetric kunokufikelela kwi-0.003mm. Ubungakanani obuphezulu bokucutshungulwa kokugaya okusicaba: ubude be-1600 * ububanzi be-800mm.

CNC

Ukugaya i-CNC ithathwa njengenye yezona zinto zisetyenziswa kakhulu kumatshini. Ukugaya i-CNC luhlobo lwesixhobo somatshini we-CNC kunye nomsebenzi oqinileyo wokucutshungulwa, iziko lomatshini eliphuhliswa ngokukhawuleza, iyunithi yomatshini oguquguqukayo, njl. njl. ziveliswa ngesiseko somatshini wokugaya we-CNC kunye nomatshini wokudinwa we-CNC, zombini azinakwahlulwa kwindlela yokugaya, uninzi lwamashishini. imisebenzi yokugaya ingagqitywa nge-3-axis, i-5-axis CNC izixhobo zomatshini. Ngeengenelo zokuguquguquka okuqinileyo, ukuchaneka okuphezulu kokusebenza, umgangatho wokucwangcisa uzinzile kunye nokusebenza kakuhle kwemveliso, olu hlobo lolawulo lwendlela lunokuqhuba ukuya kuthi ga kwi-80% yamacandelo omatshini. I-CNC inobungakanani obukhulu bokusebenza: ubude be-1300 * ububanzi 800mm.

Inkqubo yokucoca iSemiconductor Component

Ukucoca okumanzi

Ukucoca okumanzi kukusetyenziswa kweekhemikhali zokunyibilikisa okanye amanzi adibeneyo ukucoca i-wafer. Ukucoca okumanzi kunokohlulwa ngendlela yokufunxa kunye nendlela yokutshiza ngokwendlela yenkqubo, indlela yokuntywila kukuntywilisela i-wafer kwitanki yesikhongozeli equlethe isinyibilikisi sekhemikhali okanye amanzi adityanisiweyo. Indlela yokufunxa yindlela esetyenziswa ngokubanzi, ngakumbi kwiindawo ezithile ezisele zikhulile. Ukutshiza, kwelinye icala, kubandakanya ukutshiza isinyibilikisi sekhemikhali okanye amanzi adiyiniweyo kwiwafa ejikelezayo ukususa ukungcola. Indlela yokuntywila inokuqhuba iiwafa ezininzi ngaxeshanye, kwaye indlela yokutshiza inokuqhuba kuphela iwafa enye kwigumbi lokusebenza elinye ngexesha elinye. Ngokuphuhliswa kwenkqubo, iimfuno zenkqubo yokucoca ziba phezulu kwaye ziphezulu, kwaye ukusetyenziswa kwendlela yokutshiza kuya kuba kuninzi.

Icocwa ngokomisa

Njengoko igama libonisa, ukucocwa okomileyo akukona ukusetyenziswa kweekhemikhali ze-solvents okanye amanzi adibeneyo, kodwa ukusetyenziswa kwegesi okanye i-plasma ukucoca. Ngokuqhubela phambili okuqhubekayo kwee-nodes zobuchwepheshe, iimfuno zenkqubo yokucoca ziba phezulu kwaye ziphezulu, umlinganiselo wokusetyenziswa uyanda, kwaye ulwelo olulahlwayo oluveliswa ngokucoca okumanzi lukwanyuka kakhulu. Xa kuthelekiswa nokucoca okumanzi, ukucocwa okomileyo kuneendleko eziphezulu zotyalo-mali, ukusebenza kwezixhobo ezinzima kunye neemeko zokucoca ezinzima. Nangona kunjalo, ukususwa kwezinye izinto eziphilayo kunye ne-nitrides, i-oxides, ukuchaneka kokucoca okomileyo kuphezulu, umphumo uhle kakhulu.

Umlinganiselo ochanekileyo

Sineetalente kuphando lwezinto eziphathekayo, uphuhliso lwemveliso, ukuyila, ukuvelisa kunye nolawulo lomgangatho, kwaye sineseti epheleleyo yokuchaneka komatshini kunye nezixhobo zokuvavanya: ukulungelelanisa ezintathu, imitha yobunzima, imitha ye-concentricity, isixhobo sokulinganisa i-diameter yangaphandle, imitha ye-cylindricity yezixhobo zokuvavanya ukuchaneka. Inkqubo yokuvelisa engqongqo kunye nemveliso echanekileyo ephezulu kunye nezixhobo zokuvavanya ukuqinisekisa umgangatho ophezulu weemveliso.

DLC Coating

Iitafile ze-wafer carrier / gripper zisetyenziselwa ukuqulatha i-Si, i-SiC, i-GaAs, i-Gan, kunye nezinye iifestile ze-semiconductor kwiinkqubo ezahlukeneyo ze-semiconductor, ukusuka ekubhaqweni ukuya kwi-lithography, kunye nezinye izicelo ezichanekileyo eziphezulu, kubandakanywa izindlu ezinkulu, ezithambileyo eziguquguqukayo zepaneli ezibonisa , MEMS, kunye neeseli zebhayoloji. Iingubo ze-DLC zineepropati ezininzi ezinqwenelekayo, ezifana nokuxhathisa ixesha elide kunye ne-thermal conductivity ephezulu, ukwandisa ubomi bemveliso, ukugcina ukuchaneka, kunye nokunciphisa ukungqubuzana kunye nokungcoliswa. I-vacuum gripper iquka umzimba oqinileyo onezinto ezininzi zokubamba kumphezulu we-wafer okanye ipaneli, kwaye ukutenxa kwendawo yonke kunye ne-flatness yendawo ilinganiswa ngee-nanometers, kulo mzekelo, ingxaki ngokufaka i-DLC yokwambathisa kuwo wonke umphezulu we-nanometers. i-gripper kukuba ukungafani kokwandisa kwe-thermal kunokukhokelela ekulahlekelweni kwe-flatness.

I-Teflon™ i-fluoropolymer yokwenziwa kwe-semiconductor

Ekhaya

Ekhaya