Fasahar Fasaha

Ƙuntataccen tsari na samarwa da ingantaccen samarwa & kayan gwaji don tabbatar da ingancin samfuran.

Tsarin Busassun Matsawa

Dry latsa yana daya daga cikin mafi yadu amfani gyare-gyaren tsari, babban abũbuwan amfãni ne high gyare-gyare yadda ya dace, kananan size sabawa da gyare-gyaren kayayyakin, musamman dace da wani iri-iri na kananan sashe kauri na yumbu kayayyakin, kamar yumbu bawul core, yumbu farantin, yumbu farantin. zobe...da sauransu.

Tsarin Latsa Istatic da Halaye

Isostatic Pressing Molding Yana da Fa'idodi masu zuwa akan Ƙarfe Mutuwar Ƙarfe:

Ceramic Sintering

Ceramic blank ya ƙunshi mutane da yawa m barbashi kafin sintering, akwai babban adadin pores a cikin jiki, da porosity ne kullum 35% ~ 60% (wato, dangi yawa na blank ne 40% ~ 65%), ƙayyadaddun ƙimar ya dogara da halaye na foda kanta da hanyar yin gyare-gyare da fasaha da aka yi amfani da su. Lokacin da m blank ne mai tsanani a high zafin jiki, da barbashi a cikin blank canja wuri, bayan kai wani zazzabi, da blank shrinks, da hatsi girma faruwa, tare da kawar da pores, kuma a karshe blank zama m polycrystal yumbu abu a zazzabi da ke ƙasa da wurin narkewa, ana kiran wannan tsari sintering.

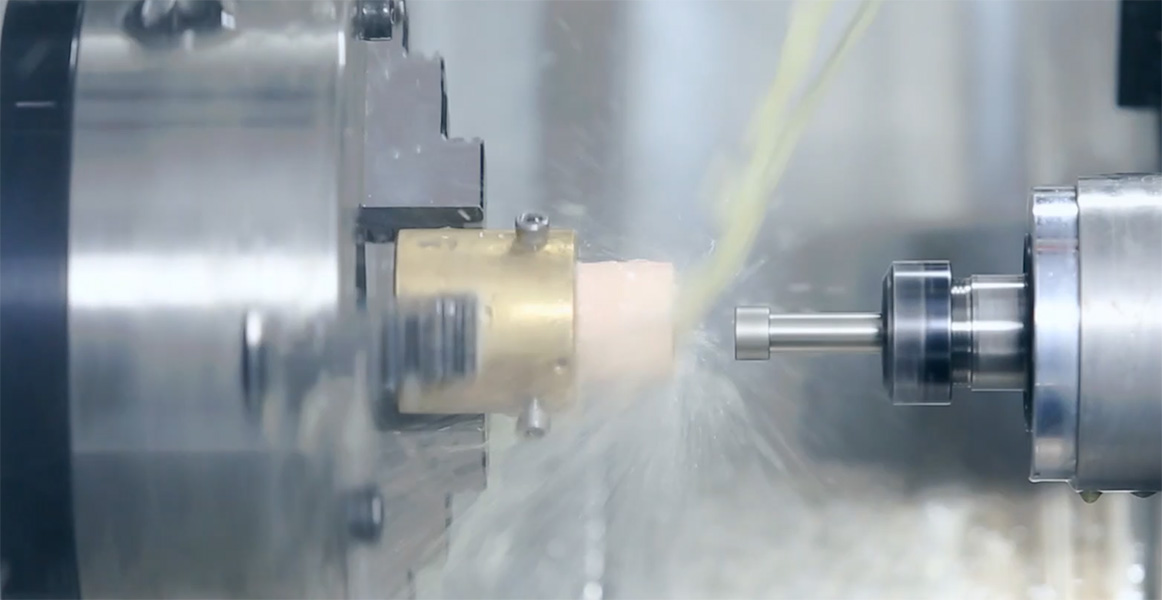

Nikawar Ciki Da Waje

Ciki da waje madauwari nika (kuma aka sani da cibiyar nika) da ake amfani da su nika m madauwari surface da kafada na workpiece. Ana ɗora kayan aikin akan cibiyar kuma ana juya shi ta na'urar da ake kira direban cibiyar. Ana jujjuya ƙafafun niƙa da kayan aiki a cikin gudu daban-daban ta wasu injuna daban. Ana iya daidaita matsayin matse samfurin a kusurwa don samar da taper. Akwai nau'ikan diamita na waje guda biyar (OD) nika, diamita na ciki (ID) niƙa, niƙa naushi, niƙa mai rarrafe da niƙa mara tsakiya.

Niƙa Diamita na Waje

Nika diamita na waje yana niƙa a saman saman wani abu tsakanin tsakiya da tsakiya. Cibiyar ita ce tantanin ƙarewa tare da batu wanda ke ba da damar abu don juyawa. Lokacin da dabaran niƙa ke hulɗa da abin, motar niƙa ita ma tana juyawa ta hanya ɗaya. Wannan yana nufin cewa lokacin da aka tuntuɓar su, saman biyun za su yi tafiya ta hanyoyi daban-daban, wanda zai sa aikin ya kasance mafi kwanciyar hankali da raguwa.

Niƙa Diamita na Ciki

Nika diamita na ciki yana niƙa a cikin abu. Nisan dabaran niƙa koyaushe yana ƙasa da faɗin abin. Abun yana riƙe da madaidaicin, wanda kuma yana jujjuya abin da ke wurin. Kamar yadda ake niƙa diamita na waje, dabaran da abu suna juyawa ta wurare dabam-dabam ta yadda hanyar tuntuɓar saman biyun inda niƙa ke faruwa ya saba wa juna.

Nika mai lebur

Nika lebur ita ce aikin niƙa da aka fi sani. Fasaha ce da ke amfani da injin niƙa mai jujjuya don niƙa saman ƙarfe ko kayan da ba na ƙarfe ba don cire oxide Layer da ƙazantar da ke saman kayan aikin, ta yadda za a ƙara tace samansa. Lebur niƙa kayan aikin injin ne da aka ƙera don samar da ingantattun filaye masu niƙa, ko girman girma ko ƙarewar ƙasa. Takamaiman daidaito na lebur grinder ya dogara da nau'insa da amfaninsa, diamita shine 300mm diski, daidaiton planimetric zai iya kaiwa 0.003mm. Matsakaicin girman aiki na lebur niƙa: tsawon 1600 * nisa 800mm.

CNC

Ana ɗaukar niƙan CNC a matsayin ɗayan ayyukan da aka fi amfani da su a cikin injina. CNC milling wani nau'i ne na kayan aikin injin CNC tare da aikin sarrafawa mai ƙarfi, cibiyar haɓaka kayan aiki da sauri, sashin injin sassauƙa, da sauransu ana samar da su akan na'urar milling CNC da na'ura mai ban sha'awa na CNC, duka biyun ba su iya rabuwa da hanyar niƙa, yawancin masana'antu. Ana iya kammala ayyukan niƙa ta hanyar 3-axis, 5-axis CNC kayan aikin injin. Tare da fa'idodin daidaitawa mai ƙarfi, daidaiton aiki mai girma, ingantaccen ingantaccen aiki da ingantaccen samarwa, wannan nau'in sarrafa hanyar yana iya aiwatarwa har zuwa 80% na sassan injina. CNC yana da matsakaicin girman machining: tsawon 1300* nisa 800mm.

Tsarin Tsabtace Kayan Semiconductor

Wet Cleaning

Tsabtace rigar shine amfani da abubuwan kaushi na sinadarai ko ruwan da aka cire don tsaftace wafer. Ana iya raba tsaftacewar rigar zuwa hanyar jiƙa da kuma hanyar fesa bisa ga hanyar tsari, hanyar jiƙa ita ce a nutsar da wafer a cikin tanki mai ɗauke da kaushi na sinadari ko ruwa mai narkewa. Hanyar jiƙa hanya ce da ake amfani da ita sosai, musamman ga wasu manyan nodes. Fesa, a daya bangaren, ya hada da fesa wani kaushi na sinadari ko kuma ruwan da ba ya dadewa a kan waina mai jujjuyawa don cire datti. Hanyar jiƙa na iya sarrafa wafers da yawa a lokaci guda, kuma hanyar fesa za ta iya aiwatar da wafer ɗaya kawai a ɗakin aiki ɗaya a lokaci guda. Tare da ci gaba da tsarin, abubuwan da ake buƙata na tsarin tsaftacewa suna karuwa da girma, kuma yin amfani da hanyar fesa yana karuwa sosai.

Bushewar Tsabtatawa

Kamar yadda sunan ya nuna, bushewar bushewa ba yin amfani da abubuwan kaushi na sinadarai ba ne ko kuma ruwan da aka lalatar da shi ba, amma amfani da iskar gas ko plasma don tsaftacewa. Tare da ci gaba da ci gaba da nodes na fasaha, abubuwan da ake bukata na tsarin tsaftacewa sun zama mafi girma kuma mafi girma, yawan amfanin da ake amfani da shi kuma yana karuwa, kuma ruwan sharar gida da aka samar ta hanyar tsaftacewa mai tsabta yana karuwa sosai. Idan aka kwatanta da rigar tsaftacewa, tsaftacewa mai bushe yana da babban farashin zuba jari, hadaddun kayan aiki da yanayin tsaftacewa mai tsanani. Duk da haka, don kawar da wasu kwayoyin halitta da nitrides, oxides, daidaitattun tsaftacewa bushe ya fi girma, sakamakon yana da kyau.

Daidaitaccen Ma'auni

Muna da hazaka a cikin bincike na kayan aiki, haɓaka samfuri, ƙira, masana'antu da sarrafa inganci, kuma muna da cikakkun saiti na mashin ɗin ƙira da kayan gwaji: daidaitawa guda uku, mitar rashin ƙarfi, mita mai ƙarfi, kayan auna diamita na waje, mitar cylindricity na ainihin kayan gwaji. Ƙuntataccen tsari na samarwa da ingantaccen samarwa & kayan gwaji don tabbatar da ingancin samfuran.

Farashin DLC

Ana amfani da tebur mai ɗaukar kaya / gripper don ƙunsar Si, SiC, GaAs, Gan, da sauran wafers na semiconductor a cikin matakai daban-daban na semiconductor, daga ganowa zuwa lithography, da sauran aikace-aikacen madaidaicin madaidaicin buƙatun, gami da manyan gidaje, nunin fa'ida mai sassauƙa na bakin ciki. , MEMS, da kwayoyin halitta. Rubutun DLC suna da kaddarorin kyawawa da yawa, kamar juriya mai ɗorewa da haɓakar zafin jiki mai ƙarfi, don haɓaka rayuwar samfur, kiyaye daidaito, da rage gogayya da gurɓatawa. The injin gripper kunshi wani m jiki tare da mahara gripper a kan surface na wafer ko panel, da kuma sabawa na overall da na gida flatness aka auna a nanometers, a cikin wannan yanayin, matsalar da ake ji a DLC shafi a kan dukan surface na. gripper shine rashin daidaituwa na haɓakar thermal na iya haifar da asarar flatness.

Teflon™ fluoropolymer don masana'antar semiconductor

Gida

Gida