Teknụzụ mmepụta

Usoro mmepụta siri ike na mmepụta zuru oke & ngwa nyocha iji hụ na ngwaahịa dị elu.

Usoro ịpị akọrọ

Mpịakọta akọrọ bụ otu n'ime usoro ịkpụzi a na-ejikarị eme ihe, uru ndị bụ isi bụ arụmọrụ ịkpụzi dị elu, obere nha nha nke ngwaahịa a kpụrụ akpụ, nke dabara adaba maka obere akụkụ dị iche iche nke ngwaahịa seramiiki, dị ka seramiiki valvụ isi, efere seramiiki, seramiiki. mgbanaka... wdg.

Usoro Mpịakọta Isostatic na Njirimara

Isostatic Pressing Molding nwere uru ndị a maka ịkpụzi ígwè anwụ anwụ:

Ceramic Sintering

Seramiiki oghere mejupụtara ọtụtụ irighiri ihe siri ike nke onye ọ bụla n'otu n'otu n'ihu sintering, enwere ọnụ ọgụgụ dị ukwuu nke pores na ahụ, porosity bụ n'ozuzu 35% ~ 60% (ya bụ, njupụta nke oghere ahụ bụ 40% ~ 65%), uru a kapịrị ọnụ dabere na njirimara nke ntụ ntụ n'onwe ya na usoro ịkpụzi na teknụzụ eji. Mgbe oghere siri ike na-ekpo ọkụ na okpomọkụ dị elu, ihe ndị dị na nnyefe oghere, mgbe ha rutere ụfọdụ okpomọkụ, oghere ahụ na-ebelata, mkpụrụ osisi na-eto eto, na-esonyere na mkpochapụ nke pores, na n'ikpeazụ oghere na-aghọ ihe polycrystal siri ike seramiiki na. okpomọkụ dị n'okpuru ebe mgbaze, a na-akpọ usoro a sintering.

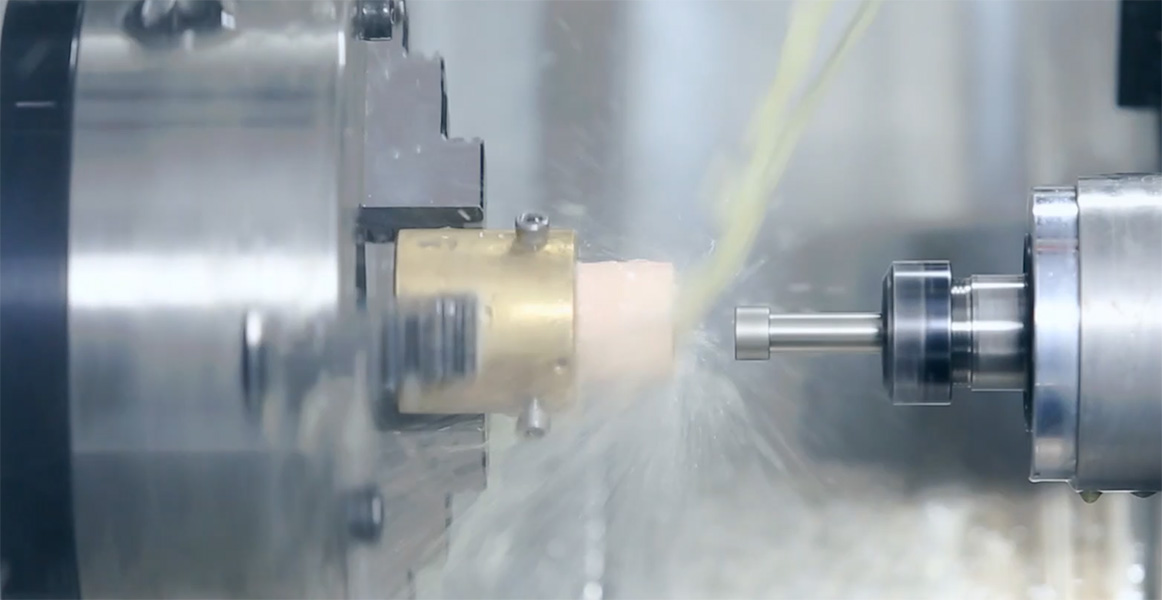

Echichi okirikiri nke ime na mpụga

N'ime na mpụta okirikiri egweri (nke a makwaara dị ka etiti egweri) na-eji na-egweri mpụta okirikiri elu na ubu nke workpiece. The workpiece na-ndokwasa na etiti na-atụgharị site na ngwaọrụ a na-akpọ center ọkwọ ụgbọala. A na-atụgharị wiil ndị na-egweri ihe na ihe ndị na-arụ ọrụ n'ọsọ dị iche iche site na moto dị iche iche. Enwere ike idozi ọnọdụ njigide nke ngwaahịa ahụ n'akụkụ akụkụ iji mepụta taper. Enwere ụdị dayameta mpụga ise (OD) egweri, n'ime dayameta (ID) egweri, ọkpọ ọkpọ, creep ndepụta egweri na centerless egweri.

Echicha dayameta nke mpụga

Iri dayameta nke mpụga na-egweri n'elu elu ihe dị n'etiti etiti na etiti. Ebe etiti bụ cell njedebe nwere isi ihe na-enye ohere ka ihe ahụ gbanwee. Mgbe wheel na-egweri na kọntaktị na ihe ahụ, wiil egweri na-atụgharịkwa n'otu ụzọ ahụ. Nke a pụtara n'ụzọ dị irè na mgbe a kpọtụrụ ya, elu abụọ ahụ ga-agagharị n'akụkụ ndị ọzọ, nke na-eme ka ọrụ ahụ dịkwuo nkwụsi ike ma ghara igbochi ya.

Ngwunye dayameta nke ime

Iri dayameta nke ime na-egweri n'ime ihe. Obosara nke wheel na-egweri na-adịkarị ala karịa obosara nke ihe ahụ. A na-ejide ihe ahụ site na nkwụnye ahụ, nke na-atụgharịkwa ihe ahụ n'ebe ahụ. Dị nnọọ ka mpụta dayameta egweri, wheel na ihe na-atụgharị n'akụkụ dị iche iche nke mere na kọntaktị ntụziaka nke abụọ elu ebe egweri na-apụta na-emegide.

Egweri dị larịị

Igwe nri dị larịị bụ ọrụ egweri nke a na-ahụkarị. Ọ bụ nkà na ụzụ nhazi nke na-eji igwe na-agbagharị agbagharị na-atụgharị n'elu ígwè ma ọ bụ ihe ndị na-abụghị ígwè iji wepụ oyi akwa oxide na adịghị ọcha n'elu nke workpiece, iji mee ka elu ya dịkwuo mma. Igwe ihe igwe dị larịị bụ ngwa igwe emebere iji nye ebe a na-egweri nke ọma, ma nha dị oke egwu ma ọ bụ imecha elu. Ihe ziri ezi nke igwe ihe dị larịị dabere na ụdị ya na ojiji ya, dayameta bụ 300mm diski, izi ezi nke planimetric nwere ike iru 0.003mm. Oke nhazi size nke ewepụghị egweri: ogologo 1600 * obosara 800mm.

CNC

A na-ahụta igwe igwe CNC dị ka otu n'ime ọrụ a na-ejikarị eme ihe na igwe. CNC-egwe ọka bụ ụdị CNC igwe ngwá ọrụ na ike nhazi ọrụ, ngwa ngwa mepụtara machining center, mgbanwe machining unit, wdg na-emepụta na ndabere nke CNC igwe igwe na CNC na-agwụ ike igwe, ha abụọ bụ ndị kewapụrụ na-egwe ọka usoro, ọtụtụ ụlọ ọrụ mmepụta ihe. Enwere ike ịrụcha ọrụ igwe igwe site na 3-axis, 5-axis CNC ngwaọrụ. Site na uru nke ngbanwe siri ike, nhazi nhazi dị elu, nhazi nhazi kwụsiri ike na mmepụta mmepụta dị elu, ụdị njikwa ụzọ a nwere ike ịhazi ruo 80% nke akụkụ igwe. CNC nwere oke machining size: ogologo 1300* obosara 800mm.

Usoro nhicha akụkụ nke Semiconductor

Nhicha mmiri

Nhicha mmiri bụ iji kemịkalụ mgbaze ma ọ bụ mmiri deionized ihicha wafer. Enwere ike kewaa ihicha mmiri n'ime usoro ncha na usoro ịgba mmiri dịka usoro usoro ahụ si dị, usoro ịcha mmiri bụ itinye wafer n'ime tankị nke nwere ihe mgbaze kemịkal ma ọ bụ mmiri deionized. Usoro ịsa mmiri bụ usoro a na-ejikarị eme ihe, ọkachasị maka ọnụ ọnụ ụfọdụ tozuru oke. N'aka nke ọzọ, ịgbasa ihe na-agụnye ịfesa ihe mgbaze kemịkal ma ọ bụ mmiri deionized n'elu wafer na-atụgharị iji wepụ adịghị ọcha. Usoro ịsa mmiri nwere ike ịhazi ọtụtụ wafers n'otu oge, na usoro ịgbasa nwere ike ịhazi otu wafer n'otu ọnụ ụlọ ọrụ n'otu oge. Site na mmepe nke usoro ahụ, ihe ndị a chọrọ nke usoro nhicha na-adịwanye elu, na iji usoro ịgbasa na-emewanyewanyewanye.

Nhicha akọrọ

Dị ka aha ahụ na-egosi, ihicha akọrọ abụghị iji kemịkalụ ihe mgbaze ma ọ bụ mmiri deionized, kama iji gas ma ọ bụ plasma na-ehicha ya. Site na ọganihu na-aga n'ihu nke oghere teknụzụ, ihe ndị a chọrọ nke usoro nhicha ahụ na-adịwanye elu ma dị elu, ọnụ ọgụgụ nke ojiji na-arịwanye elu, na mmiri mkpofu na-emepụta site na nhicha mmiri bụkwa nnukwu mmụba. E jiri ya tụnyere ihicha mmiri, ihicha akọrọ nwere ọnụ ahịa ntinye ego dị elu, ịrụ ọrụ ngwa ngwa na ọnọdụ ihicha siri ike. Otú ọ dị, maka iwepụ ụfọdụ ogige organic na nitrides, oxides, akọrọ ihicha ziri ezi dị elu, mmetụta dị mma.

Ntụle nkenke

Anyị nwere nkà na nyocha ihe, mmepụta ngwaahịa, imewe, nrụpụta na njikwa mma, ma nwee nhazi zuru oke nke nhazi na ngwa nyocha: atọ nhazi, mita roughness, concentricity mita, mpụta dayameta nha ngwá ọrụ, cylindricity mita nke ziri ezi ule ngwá. Usoro mmepụta siri ike na mmepụta zuru oke & ngwa nyocha iji hụ na ngwaahịa dị elu.

Mkpuchi DLC

A na-eji tebụl ndị na-ebu wafer / gripper nwere Si, SiC, GaAs, Gan, na ndị ọzọ semiconductor wafers n'ụdị dị iche iche nke semiconductor, site na nchọpụta ruo lithography, na ngwa ndị ọzọ na-achọsi ike dị elu, gụnyere ụlọ buru ibu, nke dị nro na-agbanwe agbanwe ngosi panel panel. , MEMS, na mkpụrụ ndụ ndụ. Ihe mkpuchi DLC nwere ọtụtụ ihe a na-achọsi ike, dị ka nkwụsi ike na-adịgide adịgide na nrụpụta okpomọkụ dị elu, iji mee ka ndụ ngwaahịa dịkwuo elu, nọgide na-enwe izi ezi, ma belata esemokwu na mmetọ. The agụụ gripper mejupụtara a isiike ozu na multiple gripper n'elu nke wafer ma ọ bụ panel, na deviation nke mkpokọta na mpaghara flatness tụrụ na nanometers, na nke a, nsogbu na itinye a DLC mkpuchi n'elu dum elu. ihe na-ejide ya bụ na ndakọrịta mgbasawanye nke thermal nwere ike ime ka ọ ghara ịdị larịị.

Teflon™ fluoropolymer maka nrụpụta semiconductor

Ụlọ

Ụlọ